D

Deleted member 20348

Guest

Hello to all,

I hope you're well and have been enjoying your car(s).

Observation

It is improbable that the sensors are causing a fault; therefore, replacing them merely on suspicion of malfunction is not advisable. This is simple advice, but often we start with the replacement of sensors. Most sensors can undergo electrical testing for voltage supply, resistance, and by monitoring their VCDS measuring blocks, topics that are discussed in other sections of this forum.

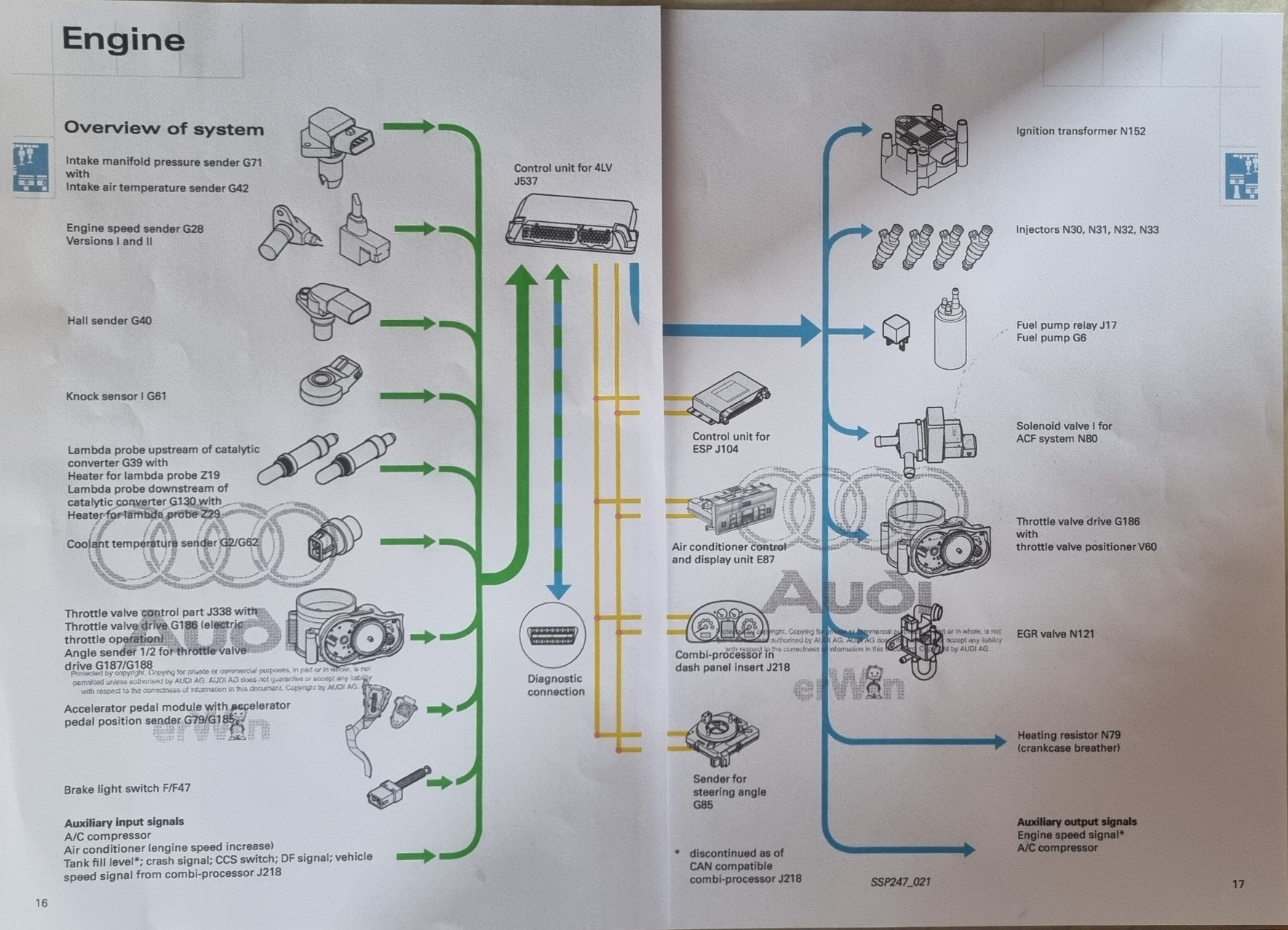

Image: AUA and BBY engine management systems

If the check engine light on the dashboard is the only sensor data available to you, it may be simpler and more cost-effective to repair a subsystem instead of a sensor. This post should prove useful for those who do not have access to VCDS software.

These subsystems include water cooling, oil circulation, piped air, and fuel delivery. Granted the fault could be electrical, that issue is often resolved by cleaning earthing points and inspecting the wiring looms. For suspected electrical issues, discussions on this topic can be found in other sections of this forum.

NOTE:

I have no qualifications in any automotive subject area.

In the spring of 2024, a second-hand BBY was fitted to my car, and the observations made in this post are based on my experience with that engine.

NOTE 2:

The AUA and BBY petrol engines produce condensation, seen as water dripping from the exhaust pipe.

Seeing a puddle of water near the exhaust should not cause alarm; it does not definitively indicate a head gasket failure. A coolant tester kit or compression leak-down test will perform this check if you suspect head gasket failure.

NOTE 3:

Discovering a minor mixture of emulsified oil and water on the underside of the oil filler cap does not necessarily indicate a head gasket failure. To minimize the likelihood of this occurrence, consider taking longer trips occasionally, or if that doesn't help, replace the camshaft and crankcase breathers.

The ECU regulates the volume of air in the intake manifold using a butterfly throttle valve.

Upon activation of the exhaust gas recirculation system (EGR), the ECU modifies the air inlet.

An active charcoal filter (ACF) and a valve that the ECU opens or closes allow the fuel tank vapour to vent into the throttle body area.

The brake booster assists with braking force by utilising the vacuum generated as air is drawn into the engine. A one-way valve prevents the air in the booster holding vessel from escaping.

A dedicated pressure release controlled crank case breather vents oil vapour and condensation to be burned off in the combustion chamber by recirculating the vapours back into the air flow below the throttle body.

Observation

If a vehicle has outdated components, it would be wise to replace the spark plugs and ignition coils. However, I did not replace them until I had changed every component of the air subsystem.

Oil typically enters the spark plug well when the engine breathers get clogged or stuck, which pressurizes the camshaft cover and leads to leaks. Discussions about repairs can be found in other threads on the forum.

All non-electrical parts of the air system should be either replaced or repaired. With access to engine diagrams from sources like 7ZAP and erWIN, we can pinpoint the components and their locations within each subsystem.

Let's get started! The VCDS has provided an engine management error code indicating a possible misfire in cylinder 4, an implausible MAP sensor signal, or a lambda sensor that is out of range. If you have access to VCDS, save and clear the faults.

If you don't have access to VCDS, you might notice symptoms such as a check-engine light, misfires, poor idling, an overheated engine, or a pronounced smell of unburnt fuel from the exhaust.

You could also experience an engine that does not start.

If you have no fault codes, it is worth thinking about a preventative maintenance checklist to work through (see items 1 through 29 below).

After following my own advice and not replacing a single sensor, the faults I experienced have gone.

To recap, the three elements that we can manage with our maintenance are fuel, air, and ignition.

Out of those three items, by far the lowest-cost parts to replace are the rubber seals, metal gaskets, rubber air hoses, and their clips and clamps.

Rubber and plastic in the engine compartment deteriorate with time because of temperature differences, vibration, shrinkage, wear, chemical exposure, and the general hardening rubber experiences as time passes.

Giving four possibilities for an air leak stemming from each run of pipe in just one location.

Addressing air anomalies is critical in this area, primarily because it situated after the air has been regulated by the Electronic Control Unit (ECU) and the position of the throttle butterfly valve.

Air leaks in this area can create fault codes due to false air.

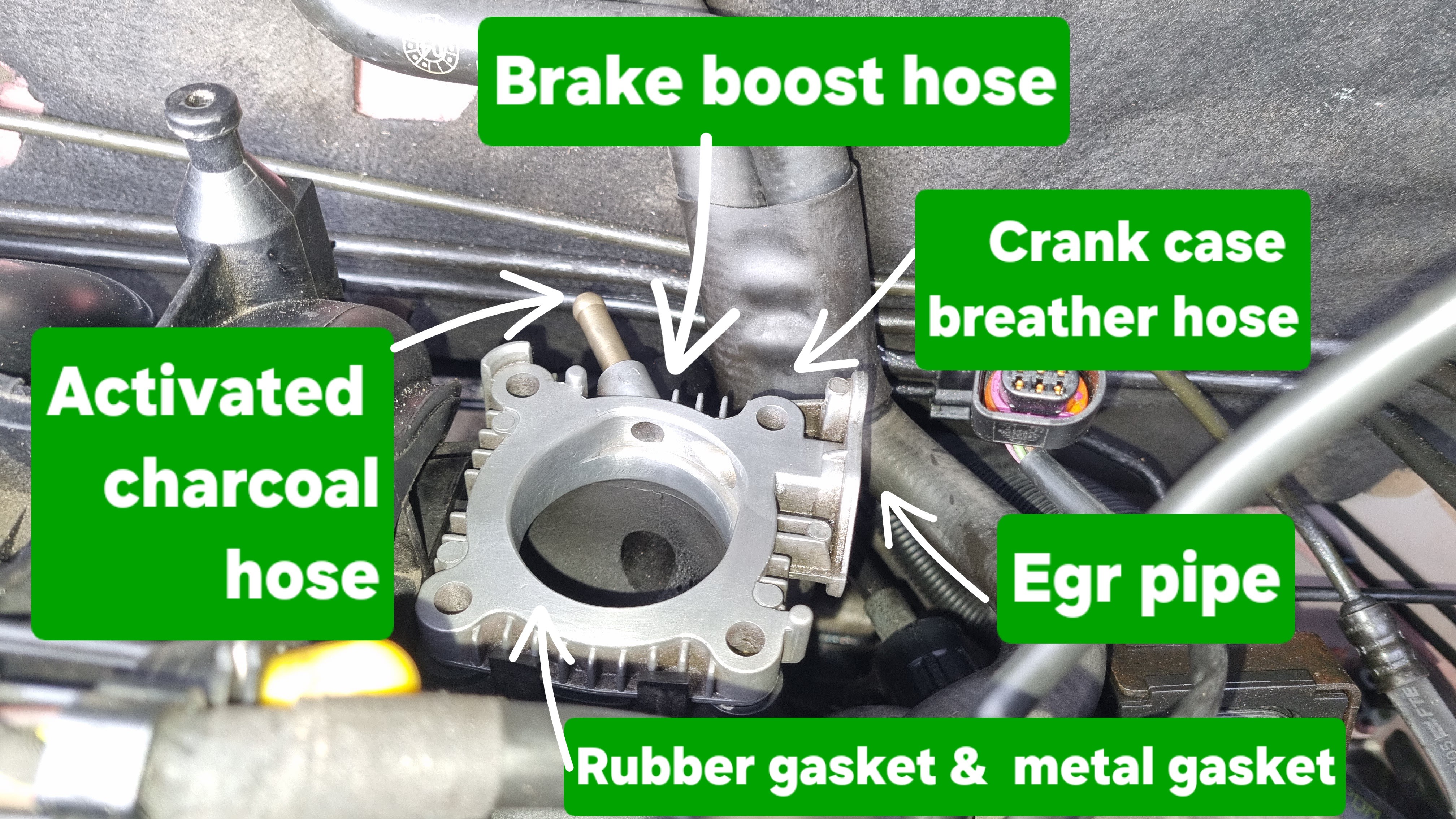

Image: Throttle Body Aluminium Mounting Bracket and Air Intake Manifold (Air Hose Connection Hub)

To recap, once false air is present, the possible error codes could be oxygen sensor, injector misfire, or manifold absolute pressure sensor (MAP)-related.

Image: AUA and BBY Engine Bay Rubber Seals, Gaskets and Hoses

1.Intake Manifold

2. Fuel Rail

3. Intake manifold seals

4. Oil level/temp sensor

5. Crankcase Breather

6. Brake Boost Hose and Check Valve

7. Manifold Absolute Pressure Sensor

8. Activated Charcoal Filter Valve and Hose

9. Crank Case Breather Pipe

10.Crank Case Breather Seals

11. Activated Charcoal Filter (ACF)

12. Dip Stick and Tube

13. Slam Panel Dipstick Holder

14. Oil Cap and Seal

15. Slam Panel Oil Filler Housing

16. Oil Filler Tube

17. Oil Filler Cap and Seal

18. Thorough Body Mating Surface

19. Throttle Body Metal Gasket

20.Throttle Body Aluminum Mounting Bracket

21. Throttle Body Aluminum Mounting Bracket Seal

22. EGR Pipe Seal

23. EGR Valve

24. EGR Valve Seal

25. Oil Pressure Sensor

26. Camshaft position sensor

27. Camshaft Breather

28. EGR Pipe

29. EGR Pipe Metal Gasket

Good Luck with your repairs!

Engine Management Diagnostic Diagram AUA BBY

I hope you're well and have been enjoying your car(s).

Introduction

Over time, management systems that control the fuel-air mixture in internal combustion engines have evolved. Computerised engine management systems have decreased pollution levels from exhaust pipes by enhancing combustion control and the utilisation of efficient catalytic converters. While engine sensors continuously relay information to the ECU, a poorly maintained subsystem may lead to erroneous fault indications from a sensor.Observation

It is improbable that the sensors are causing a fault; therefore, replacing them merely on suspicion of malfunction is not advisable. This is simple advice, but often we start with the replacement of sensors. Most sensors can undergo electrical testing for voltage supply, resistance, and by monitoring their VCDS measuring blocks, topics that are discussed in other sections of this forum.

Image: AUA and BBY engine management systems

If the check engine light on the dashboard is the only sensor data available to you, it may be simpler and more cost-effective to repair a subsystem instead of a sensor. This post should prove useful for those who do not have access to VCDS software.

These subsystems include water cooling, oil circulation, piped air, and fuel delivery. Granted the fault could be electrical, that issue is often resolved by cleaning earthing points and inspecting the wiring looms. For suspected electrical issues, discussions on this topic can be found in other sections of this forum.

NOTE:

I have no qualifications in any automotive subject area.

In the spring of 2024, a second-hand BBY was fitted to my car, and the observations made in this post are based on my experience with that engine.

NOTE 2:

The AUA and BBY petrol engines produce condensation, seen as water dripping from the exhaust pipe.

Seeing a puddle of water near the exhaust should not cause alarm; it does not definitively indicate a head gasket failure. A coolant tester kit or compression leak-down test will perform this check if you suspect head gasket failure.

NOTE 3:

Discovering a minor mixture of emulsified oil and water on the underside of the oil filler cap does not necessarily indicate a head gasket failure. To minimize the likelihood of this occurrence, consider taking longer trips occasionally, or if that doesn't help, replace the camshaft and crankcase breathers.

Subsystem: Air

The piston's downward movement draws air into the cylinder. This is achieved through the action of the AUA and BBY engine camshafts, which open the air inlet valve. There is discussion on the forum somewhere if you think you may have a valve that is stuck open.The ECU regulates the volume of air in the intake manifold using a butterfly throttle valve.

Upon activation of the exhaust gas recirculation system (EGR), the ECU modifies the air inlet.

An active charcoal filter (ACF) and a valve that the ECU opens or closes allow the fuel tank vapour to vent into the throttle body area.

The brake booster assists with braking force by utilising the vacuum generated as air is drawn into the engine. A one-way valve prevents the air in the booster holding vessel from escaping.

A dedicated pressure release controlled crank case breather vents oil vapour and condensation to be burned off in the combustion chamber by recirculating the vapours back into the air flow below the throttle body.

Observation

If a vehicle has outdated components, it would be wise to replace the spark plugs and ignition coils. However, I did not replace them until I had changed every component of the air subsystem.

Oil typically enters the spark plug well when the engine breathers get clogged or stuck, which pressurizes the camshaft cover and leads to leaks. Discussions about repairs can be found in other threads on the forum.

All non-electrical parts of the air system should be either replaced or repaired. With access to engine diagrams from sources like 7ZAP and erWIN, we can pinpoint the components and their locations within each subsystem.

Let's get started! The VCDS has provided an engine management error code indicating a possible misfire in cylinder 4, an implausible MAP sensor signal, or a lambda sensor that is out of range. If you have access to VCDS, save and clear the faults.

If you don't have access to VCDS, you might notice symptoms such as a check-engine light, misfires, poor idling, an overheated engine, or a pronounced smell of unburnt fuel from the exhaust.

You could also experience an engine that does not start.

If you have no fault codes, it is worth thinking about a preventative maintenance checklist to work through (see items 1 through 29 below).

After following my own advice and not replacing a single sensor, the faults I experienced have gone.

To recap, the three elements that we can manage with our maintenance are fuel, air, and ignition.

Out of those three items, by far the lowest-cost parts to replace are the rubber seals, metal gaskets, rubber air hoses, and their clips and clamps.

Rubber and plastic in the engine compartment deteriorate with time because of temperature differences, vibration, shrinkage, wear, chemical exposure, and the general hardening rubber experiences as time passes.

Start Point

There are four pipes/hoses that connect to the intake system after the throttle body butterfly valve.Giving four possibilities for an air leak stemming from each run of pipe in just one location.

Addressing air anomalies is critical in this area, primarily because it situated after the air has been regulated by the Electronic Control Unit (ECU) and the position of the throttle butterfly valve.

Air leaks in this area can create fault codes due to false air.

Image: Throttle Body Aluminium Mounting Bracket and Air Intake Manifold (Air Hose Connection Hub)

To recap, once false air is present, the possible error codes could be oxygen sensor, injector misfire, or manifold absolute pressure sensor (MAP)-related.

Image: AUA and BBY Engine Bay Rubber Seals, Gaskets and Hoses

1.Intake Manifold

2. Fuel Rail

3. Intake manifold seals

4. Oil level/temp sensor

5. Crankcase Breather

6. Brake Boost Hose and Check Valve

7. Manifold Absolute Pressure Sensor

8. Activated Charcoal Filter Valve and Hose

9. Crank Case Breather Pipe

10.Crank Case Breather Seals

11. Activated Charcoal Filter (ACF)

12. Dip Stick and Tube

13. Slam Panel Dipstick Holder

14. Oil Cap and Seal

15. Slam Panel Oil Filler Housing

16. Oil Filler Tube

17. Oil Filler Cap and Seal

18. Thorough Body Mating Surface

19. Throttle Body Metal Gasket

20.Throttle Body Aluminum Mounting Bracket

21. Throttle Body Aluminum Mounting Bracket Seal

22. EGR Pipe Seal

23. EGR Valve

24. EGR Valve Seal

25. Oil Pressure Sensor

26. Camshaft position sensor

27. Camshaft Breather

28. EGR Pipe

29. EGR Pipe Metal Gasket

Good Luck with your repairs!

Engine Management Diagnostic Diagram AUA BBY

Last edited by a moderator: