lavandism

Member

Hello there,

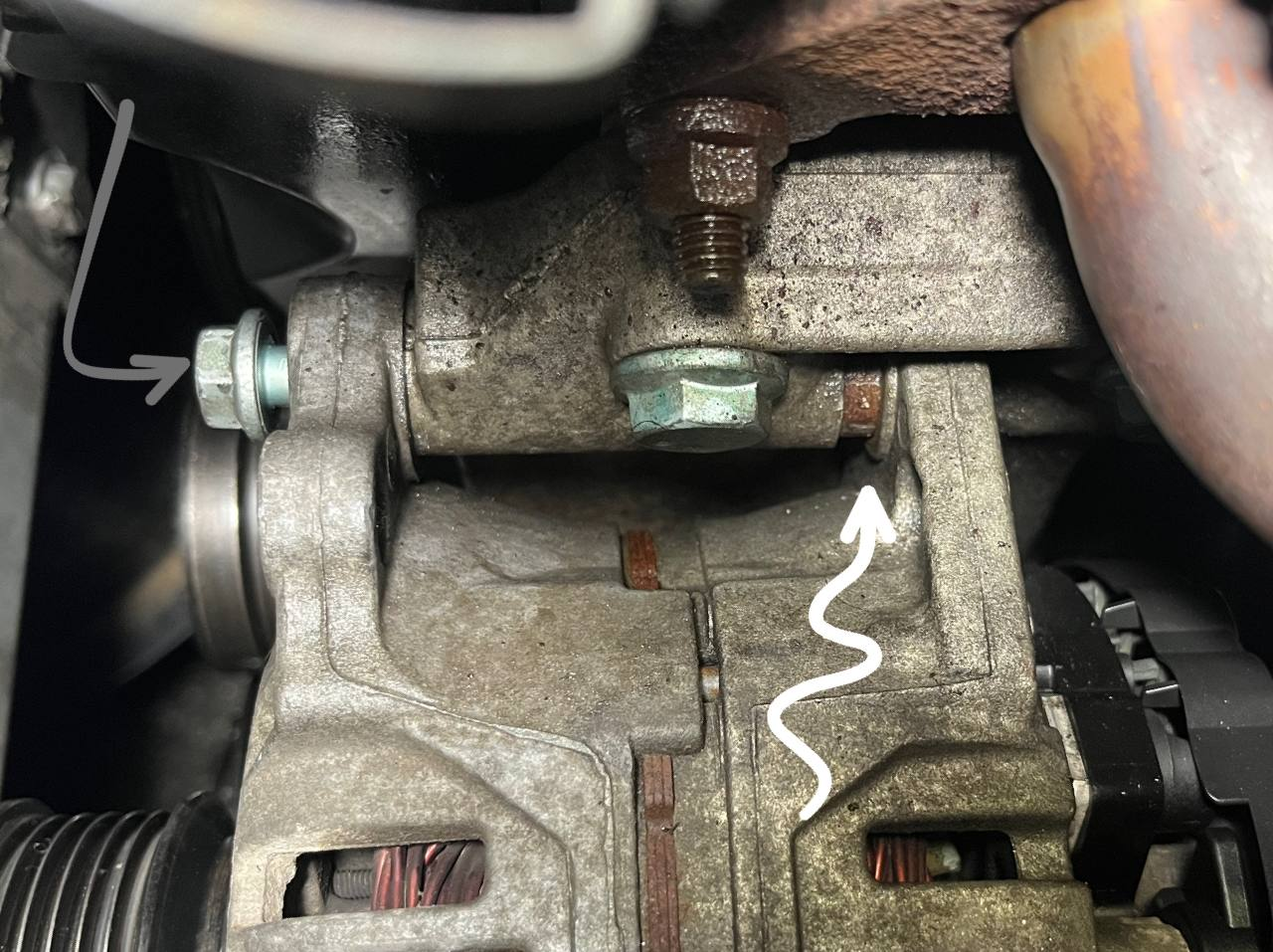

my alternator is stuck on rusted bushings (white arrow). Tapping the nut (grey arrow) with a hammer to push it out while bathing in wd40 did not really help.

I am currently considering to get a proper rust removing penetrating oil, but I wonder if that will do any difference. Anybody has dealt with something similar?

my alternator is stuck on rusted bushings (white arrow). Tapping the nut (grey arrow) with a hammer to push it out while bathing in wd40 did not really help.

I am currently considering to get a proper rust removing penetrating oil, but I wonder if that will do any difference. Anybody has dealt with something similar?