Alan_uk

A2OC Donor

I'm waiting for the shocks. Ordered from APT but transpires coming from Germany. Seems to be stuck in customs in Essex.  I hope it comes in time to fit before a long journey.

I hope it comes in time to fit before a long journey.

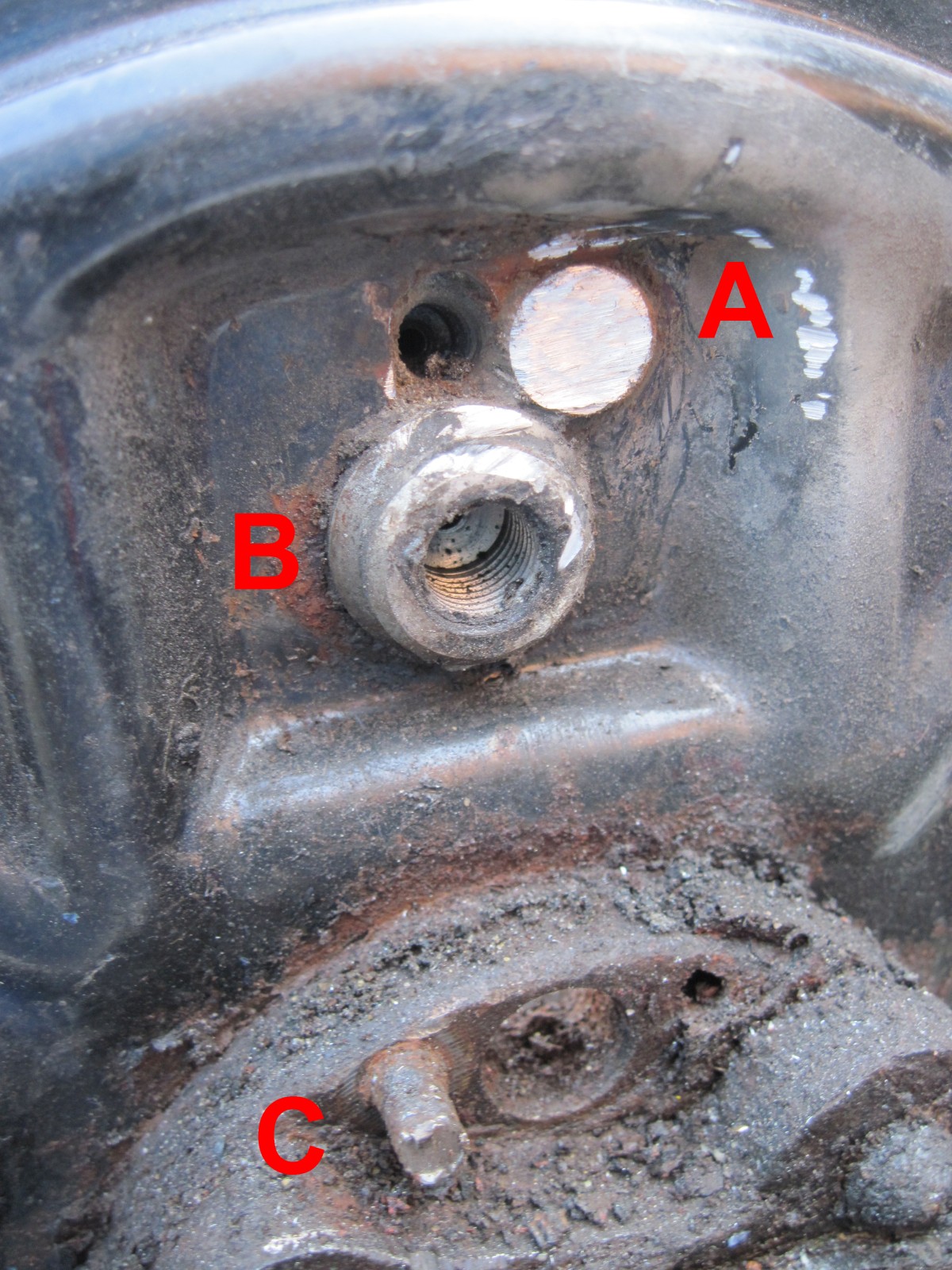

Meanwhile I dremel off the ABS sensor hex bolt head. I removed the ABS sensor but the remains of the bolt (C in the photo) wont shift using pipe pliers and mole grips - just gets worn away. Yes, it's had numerous dousings of Plus Gas penetrating fluid. Anyway, I concluded the hex bolt goes into the hub so if that gets replaced it doesn't matter.

But the hex bolt to the cylinder is more problematic. I dremel the head off (A in the photo) but it wont shift. I cannot figure out if the back plate has a raised area for this bolt. If not then I can dremel a bit more. Anyone know?

It appears that the cylinder bleed hole B is not fixed to the back plate.

Meanwhile I dremel off the ABS sensor hex bolt head. I removed the ABS sensor but the remains of the bolt (C in the photo) wont shift using pipe pliers and mole grips - just gets worn away. Yes, it's had numerous dousings of Plus Gas penetrating fluid. Anyway, I concluded the hex bolt goes into the hub so if that gets replaced it doesn't matter.

But the hex bolt to the cylinder is more problematic. I dremel the head off (A in the photo) but it wont shift. I cannot figure out if the back plate has a raised area for this bolt. If not then I can dremel a bit more. Anyone know?

It appears that the cylinder bleed hole B is not fixed to the back plate.