jackwickers2003

Member

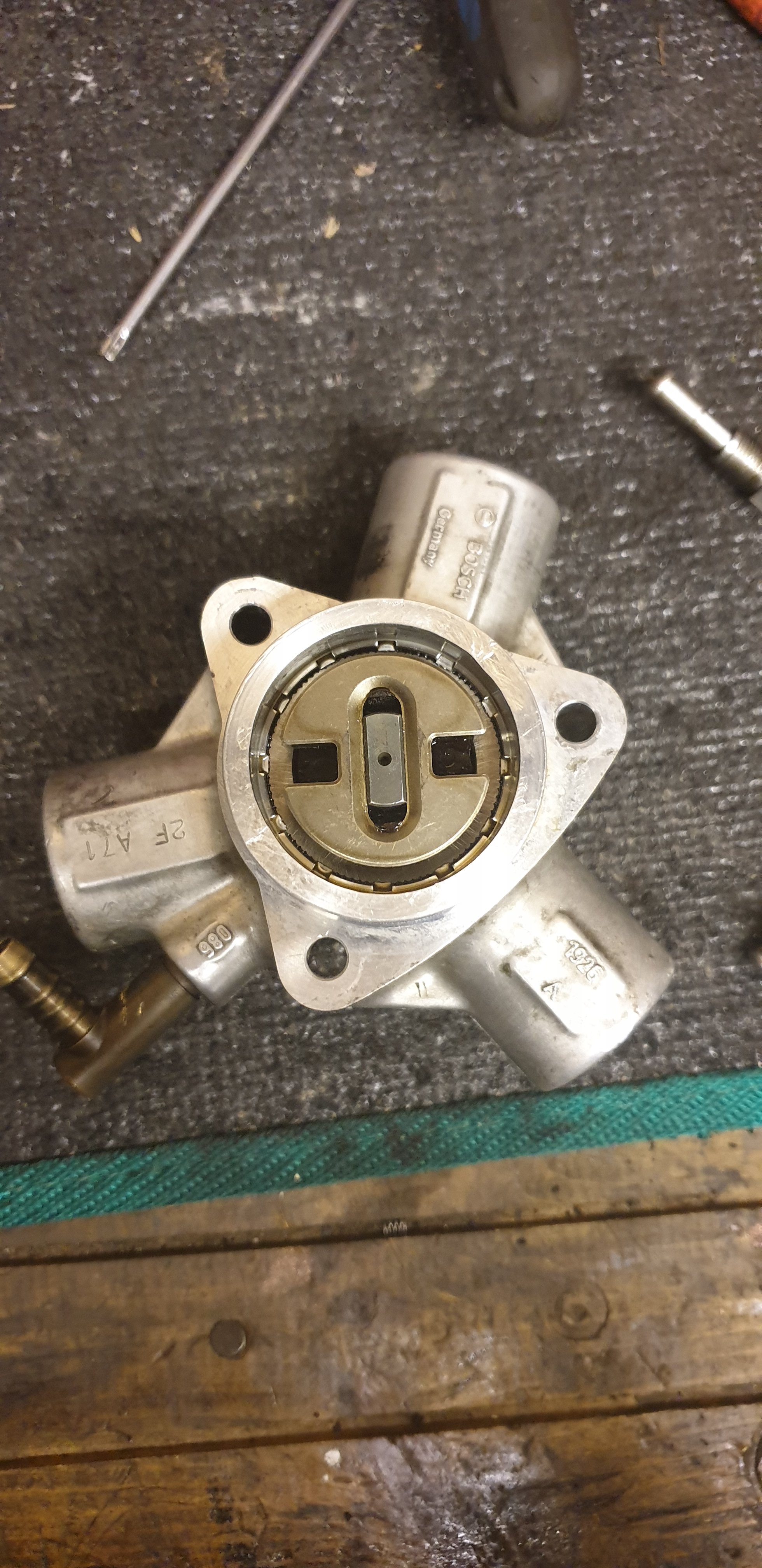

Some pictures for all you 1.6 FSI owners that have high pressure fuel pumps. Mine started to fail due to worn seals. Normally a very expensive fix but i managed to sort it for the cost of rubber o rings. I hope this helps people understand how to fix it their selves in the future and save hundreds!

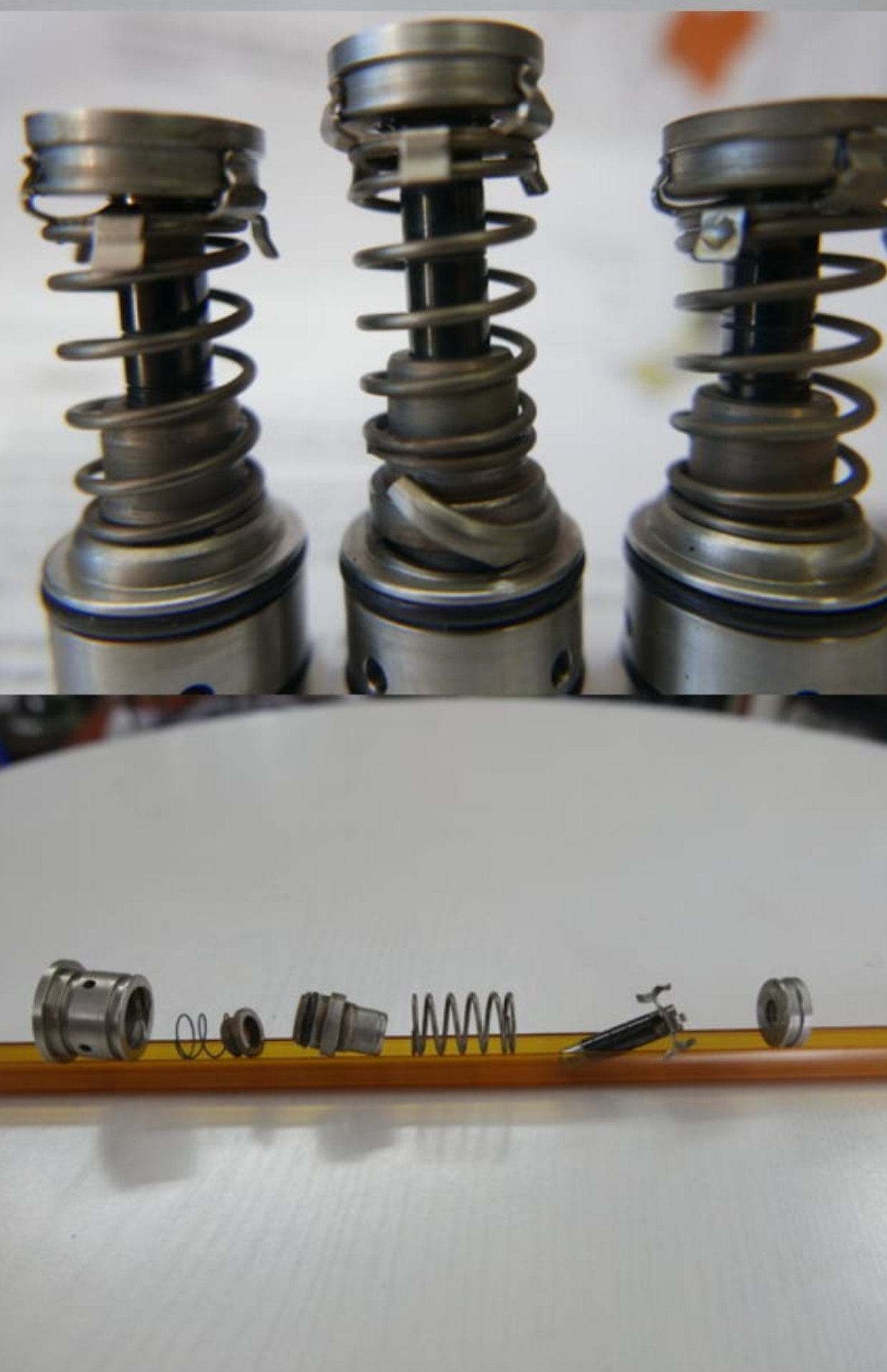

The picture above shows the internals of my high pressure fuel pump. The next picture shows which o ring failed causing loss of power above 3k revvs.

The next few pictures are screenshots that hopefully help people in the future.

The picture above shows the internals of my high pressure fuel pump. The next picture shows which o ring failed causing loss of power above 3k revvs.

The next few pictures are screenshots that hopefully help people in the future.