Alan_uk

A2OC Donor

I fitted this socket to facilitate a PV panel to charge the A2. During lockdown the battery would gradually become weaker due to the alarm system being on 24/7.

I did consider a OEM socket but this would necessitate removing the left boot panel that goes over the rear nearside wheel, and I read they can be a pain to remove and refit.

On ebay I bought:

12V USB Car Cigarette Lighter Waterproof Socket Charger Power Adapter Fuse Cable

Note that the cable terminates in eyelet connectors. The cap on the socket is not essential but a nice touch.

Car Cigarette Lighter Socket Plug Connector 12v Male 5A with LED Car Van Caravan

Note that the plug is a right angled plug. You see why later. I also removed the LED and resistor. These plugs need the wire soldering which is a bit fiddly.

...

...

Photos: ebay items

The first task was to locate a suitable position that allowed an easy cable run to the battery. Given the socket cable length then this was going to be on the nearside of the boot.

I tested the space next to first aid kit slot by drilling a very small hole circa 1mm and probing with a thin wire. My first hole was about 20mm or so to the right of the first aid kit slot, but here I felt something. However, it seemed promising so I pulled away the boot liner and found a gap in the corner of the wheel arch bulk head and inserted an endoscope (I have an inexpensive Depstech that is powered by a USB rechargeable battery and displays the image on a mobile phone via wi-fi). Note that to pull away the boot liner I removed the two load hooks.

Photo: Boot lining showing access to behind arch

As you can see there is another bulkhead just to the right of the first aid kit slot

Photo: Behind the boot liner at the bottom corner

Further up I could see my wire. In the end I decided to drill a hole exactly midway between the first aid kit slot and the false floo9r runner.

Photo: Boot lining with cut hole and wire showing cable route

Note the wire has reached the bottom corner. In the next photo you can see the bulkhead that is just to the right of the first aid kit slot and you can see one of the yellow clips that secure the boot lining to another bulkhead.

Photo Looking into the cut hole showing one bulk head

I used a hole cutter on an electric drill. I thought it fortunate I had a hole cutter the same size as the socket but given the soft nature of the boot lining then the socket hole was very slightly too big.

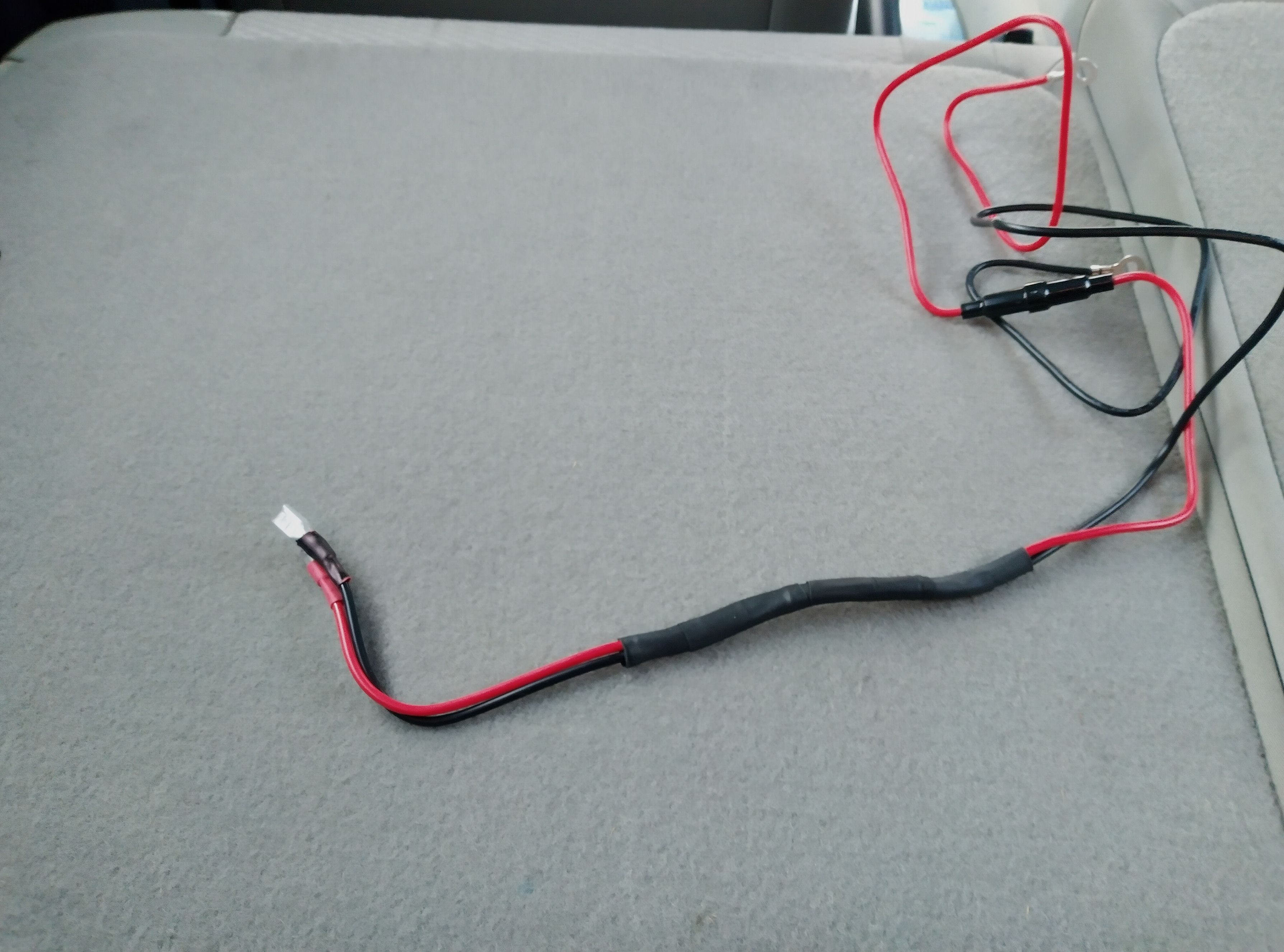

I next protected the 12V cable to the socket with a number of layers of shrink wrap of increasing size. Note initially I got the position wrong, hence a rather long shrink wrap.

Photo: Cable from socket to battery with inline fuse

I then taped the socket push on connectors to the wire at the bottom and pulled them through and connected to the socket. I then wrapped the metal casing of the socket with tape.

Photo: Socket with white insulating tape

Next I found a route to the battery terminals where I fitted the eyelets to the nuts & bolts securing the battery terminals. I kept the inline fuse at 10A (max. power of the cable & socket is 120W). Note I did change the fuses in the plugs to 5A to suit the PV panel.

Sorry no photos but I recall cutting away a small amount of plastic around the plastic tray holding the tool kit so the cable was not squashed by the floor.

continues....

I did consider a OEM socket but this would necessitate removing the left boot panel that goes over the rear nearside wheel, and I read they can be a pain to remove and refit.

On ebay I bought:

12V USB Car Cigarette Lighter Waterproof Socket Charger Power Adapter Fuse Cable

Note that the cable terminates in eyelet connectors. The cap on the socket is not essential but a nice touch.

Car Cigarette Lighter Socket Plug Connector 12v Male 5A with LED Car Van Caravan

Note that the plug is a right angled plug. You see why later. I also removed the LED and resistor. These plugs need the wire soldering which is a bit fiddly.

Photos: ebay items

The first task was to locate a suitable position that allowed an easy cable run to the battery. Given the socket cable length then this was going to be on the nearside of the boot.

I tested the space next to first aid kit slot by drilling a very small hole circa 1mm and probing with a thin wire. My first hole was about 20mm or so to the right of the first aid kit slot, but here I felt something. However, it seemed promising so I pulled away the boot liner and found a gap in the corner of the wheel arch bulk head and inserted an endoscope (I have an inexpensive Depstech that is powered by a USB rechargeable battery and displays the image on a mobile phone via wi-fi). Note that to pull away the boot liner I removed the two load hooks.

Photo: Boot lining showing access to behind arch

As you can see there is another bulkhead just to the right of the first aid kit slot

Photo: Behind the boot liner at the bottom corner

Further up I could see my wire. In the end I decided to drill a hole exactly midway between the first aid kit slot and the false floo9r runner.

Photo: Boot lining with cut hole and wire showing cable route

Note the wire has reached the bottom corner. In the next photo you can see the bulkhead that is just to the right of the first aid kit slot and you can see one of the yellow clips that secure the boot lining to another bulkhead.

Photo Looking into the cut hole showing one bulk head

I used a hole cutter on an electric drill. I thought it fortunate I had a hole cutter the same size as the socket but given the soft nature of the boot lining then the socket hole was very slightly too big.

I next protected the 12V cable to the socket with a number of layers of shrink wrap of increasing size. Note initially I got the position wrong, hence a rather long shrink wrap.

Photo: Cable from socket to battery with inline fuse

I then taped the socket push on connectors to the wire at the bottom and pulled them through and connected to the socket. I then wrapped the metal casing of the socket with tape.

Photo: Socket with white insulating tape

Next I found a route to the battery terminals where I fitted the eyelets to the nuts & bolts securing the battery terminals. I kept the inline fuse at 10A (max. power of the cable & socket is 120W). Note I did change the fuses in the plugs to 5A to suit the PV panel.

Sorry no photos but I recall cutting away a small amount of plastic around the plastic tray holding the tool kit so the cable was not squashed by the floor.

continues....