No longer member

Member

Changing a wheel front wheel bearing has been covered many times on the forum but just maybe my experience will have the odd bit of interest if you need to do it. The very best tip I have come across is this video of fitting a Skoda Fabia bearing, its the same bearing and virtually the same method.

Before you start you will need a place to work and a decent set of tools plus a few that are not so common. A ball joint tool, a 7mm allen key for the brake caliper, a M36 12 point socket for the nut on the end of the driveshaft, and a thin 16 mm spanner to help undo the drop link.

And of course the special wheel bearing kit, this also suits the VW Polo and Skoda Fabia, 72mm . It was £48 from Ebay, typical Chinese but decent quality.

I used both a wheel bearing and ABS sensor from Febi. The sensor was about £10 and the bearing £36, (other brands are available). The wheel bearing kit includes a new 12 point M36 nut and a large nylon washer. The washer (blue arrow) is not needed for the Audi.

I changed the wheel bearing not because it was faulty but because the ABS sensor was causing irritating alarms and turning off the ABS function. I had earlier replaced the ABS pickup but this had made the problem slightly worse. I was being a bit optimistic hoping this would fix the problem as the VCDS scan had indicated a ‘mechanical fault - ABS sensor’. So the only other thing is the reluctor ring (I think that’s what it is called) which goes around with the wheel. This ring looks like a bearing seal, (red arrow) and is integral with the bearing. It is just possible it could have been fixed by cleaning through the hole where the pickup fits. If trying this note where the reluctor ring fits, it is at the side of the pickup not directly underneath.

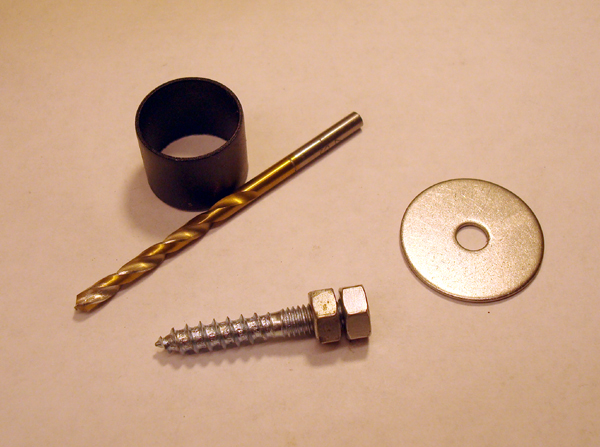

Maybe now to digress and mention the ABS wheel pickup. Chances are it is going to break after being sat in the hub for 16 plus years and be well rusted in, mine sheared off. To get the broken part out I used a wood screw/machine dowel as an extractor and it worked a treat. Drill a hole into the broken plastic sensor and screw in the wood screw side of the stud. When it is hard in there slip a tube or stack of washers over it and using a nut jack out the broken piece. I must admit I was well chuffed when that trick worked.

So the actual job is quite straight forward as per the you tube video and I have only one or two things to add.

The special too and bearing are enough to juggle with when fitting the bearings so before setting up the tool I applied a very light coat of anti-sieze and then gently tapped it into the hub a few mm just to start it and ensure it was aligned. The force used to locate the bearing must be very small as the load is going through the bearing and can potentially damage it, but that’s why there is a special tool.

The only other thing of note is that the ‘audible click’ as the bearing is pressed in does not guarantee it is fully home. With the driveshaft removed it is possible to check the bearing has been pushed all the way to the hub shoulder. If it is not fully home then the ABS sensor may not be close enough to the reluctor ring to work properly.

And I am pleased to say there are no more ABS alarms!

Before you start you will need a place to work and a decent set of tools plus a few that are not so common. A ball joint tool, a 7mm allen key for the brake caliper, a M36 12 point socket for the nut on the end of the driveshaft, and a thin 16 mm spanner to help undo the drop link.

And of course the special wheel bearing kit, this also suits the VW Polo and Skoda Fabia, 72mm . It was £48 from Ebay, typical Chinese but decent quality.

I used both a wheel bearing and ABS sensor from Febi. The sensor was about £10 and the bearing £36, (other brands are available). The wheel bearing kit includes a new 12 point M36 nut and a large nylon washer. The washer (blue arrow) is not needed for the Audi.

I changed the wheel bearing not because it was faulty but because the ABS sensor was causing irritating alarms and turning off the ABS function. I had earlier replaced the ABS pickup but this had made the problem slightly worse. I was being a bit optimistic hoping this would fix the problem as the VCDS scan had indicated a ‘mechanical fault - ABS sensor’. So the only other thing is the reluctor ring (I think that’s what it is called) which goes around with the wheel. This ring looks like a bearing seal, (red arrow) and is integral with the bearing. It is just possible it could have been fixed by cleaning through the hole where the pickup fits. If trying this note where the reluctor ring fits, it is at the side of the pickup not directly underneath.

Maybe now to digress and mention the ABS wheel pickup. Chances are it is going to break after being sat in the hub for 16 plus years and be well rusted in, mine sheared off. To get the broken part out I used a wood screw/machine dowel as an extractor and it worked a treat. Drill a hole into the broken plastic sensor and screw in the wood screw side of the stud. When it is hard in there slip a tube or stack of washers over it and using a nut jack out the broken piece. I must admit I was well chuffed when that trick worked.

So the actual job is quite straight forward as per the you tube video and I have only one or two things to add.

The special too and bearing are enough to juggle with when fitting the bearings so before setting up the tool I applied a very light coat of anti-sieze and then gently tapped it into the hub a few mm just to start it and ensure it was aligned. The force used to locate the bearing must be very small as the load is going through the bearing and can potentially damage it, but that’s why there is a special tool.

The only other thing of note is that the ‘audible click’ as the bearing is pressed in does not guarantee it is fully home. With the driveshaft removed it is possible to check the bearing has been pushed all the way to the hub shoulder. If it is not fully home then the ABS sensor may not be close enough to the reluctor ring to work properly.

And I am pleased to say there are no more ABS alarms!