D

Deleted member 20348

Guest

Hello,

I've spent an hour or so reading the following document.

Self-Study Programme 253

Direct Petrol Injection System with Bosch

Motronic MED 7

Design and Function

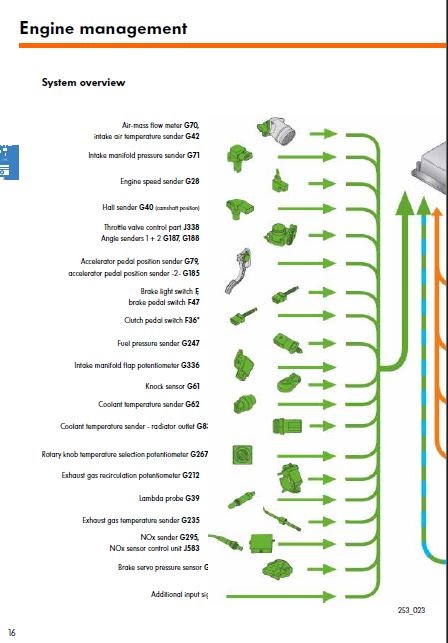

These sensors report DATA to the ECU

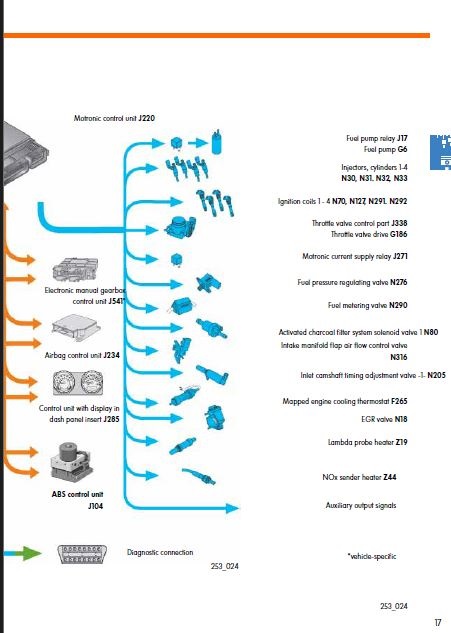

These items are controlled by the ECU

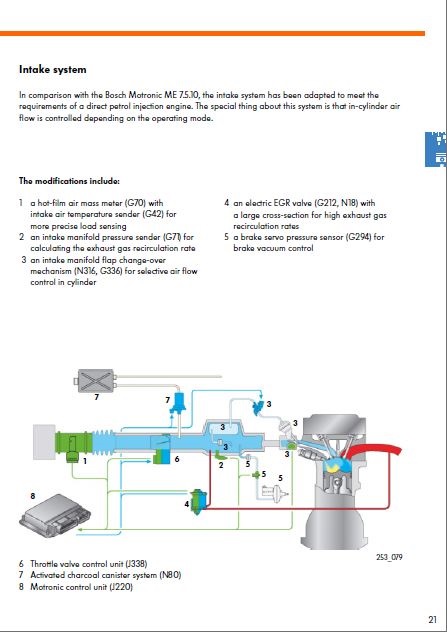

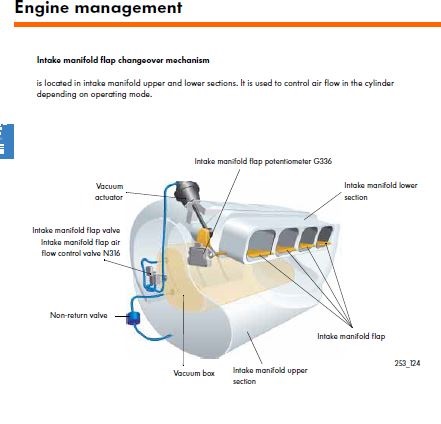

This is the air intake system and the vacuum-controlled items

The one-way valve maintains the vacuum in the vacuum box when the engine shuts off. Could this cause the start-up rattle?

The FSI is all about the air, with its three modes of combustion depending on the torque demand.

The self-study programme that this lot came from is easy to follow and from page 16, it starts to get interesting.

Especially the information provided about each component when there is a signal failure and the strategies it employs.

G294 brake servo pressure sensor

If the signal from the pressure sensor fails, the

engine will only be allowed to operate in

homogeneous charge mode.

Its full of nuggets like the one above.

My concern about this engine would be the availability of new and used parts.

I've spent an hour or so reading the following document.

Self-Study Programme 253

Direct Petrol Injection System with Bosch

Motronic MED 7

Design and Function

These sensors report DATA to the ECU

These items are controlled by the ECU

This is the air intake system and the vacuum-controlled items

The one-way valve maintains the vacuum in the vacuum box when the engine shuts off. Could this cause the start-up rattle?

The FSI is all about the air, with its three modes of combustion depending on the torque demand.

The self-study programme that this lot came from is easy to follow and from page 16, it starts to get interesting.

Especially the information provided about each component when there is a signal failure and the strategies it employs.

G294 brake servo pressure sensor

If the signal from the pressure sensor fails, the

engine will only be allowed to operate in

homogeneous charge mode.

Its full of nuggets like the one above.

My concern about this engine would be the availability of new and used parts.