You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gear Box Selector Cables, Updated.

- Thread starter PlasticMac

- Start date

A2Steve

A2OC Donor

Great to see these photos. The selector cables are not something i've been regularly asked to remove until the last few months.

On the last TDI I had in, I could't get the cables through the bulkhead for love nor money.

I see now looking at yours that the grommet is a flexible rubber on these.

On the early TDI I tried to remove them from, the grommet was a hard plastic, with locating tabs at the back.

Here's hoping I can remove the ones from the current 2002 car for you @audifan with more ease.

On the last TDI I had in, I could't get the cables through the bulkhead for love nor money.

I see now looking at yours that the grommet is a flexible rubber on these.

On the early TDI I tried to remove them from, the grommet was a hard plastic, with locating tabs at the back.

Here's hoping I can remove the ones from the current 2002 car for you @audifan with more ease.

audifan

A2OC Donor

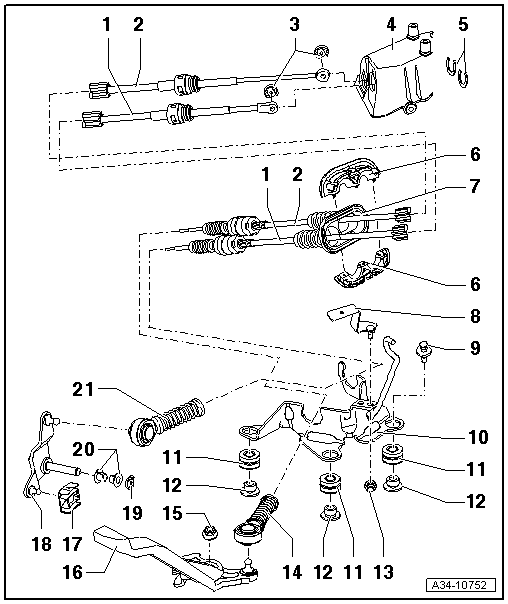

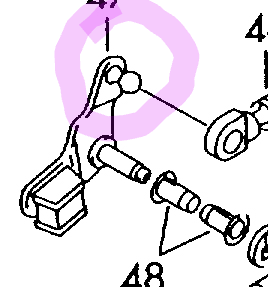

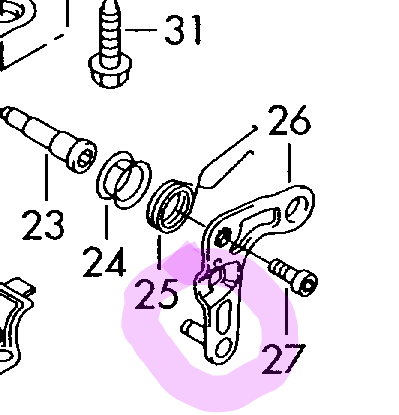

I think the ones with the rigid bulkhead plate are probably easier removed by disconnecting the cables from the gearstick end by removing the retaining washers and C clips and fed forward out the engine bay. The ones like above come into the car easy enough as the grommet can be fed through the bulkhead.

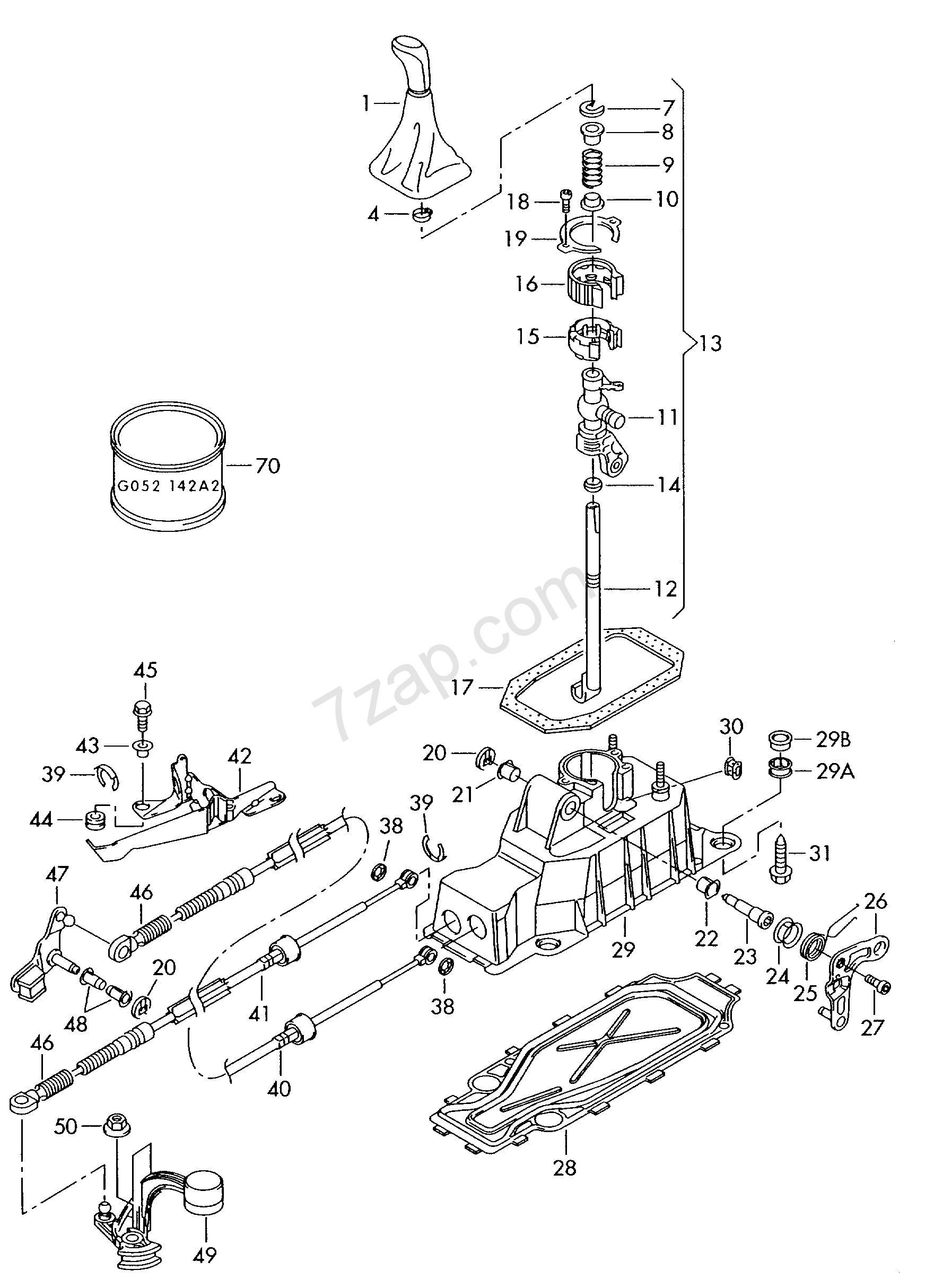

Audi Workshop Service and Repair Manuals > A2 > Power transmission | 5-speed manual gearbox 02J | Gearbox mechanics,operation, construction,diff. | Servicing selector mechanism | Removing and installing selector mechanism

A2 > Audi Workshop Service and Repair Manuals > Power transmission | 5-speed manual gearbox 02J | Gearbox mechanics,operation, construction,diff. | Servicing selector mechanism | Removing and installing selector mechanism

workshop-manuals.com

PlasticMac

Member

Can anyone help with the diameter of fixed pin, on which the rod end bearing fits, (at the gear tower end), and the ball diameter at the gearbox end please.

Mac.

Mac.

George Hogg

A2OC Donor

Hi folks, I was wondering if we’d got any progress on getting new cables identified or made? If not does anyone have a set in any condition to use as patterns?

George Hogg

A2OC Donor

Thank you, I’d need a set of cables, in any condition, to go through the boxes at a local motor factor and compare. I’ve got a set of Fabia ones which have the pin and clevis ends on the gearbox but the ends swap. I just need some old A2 cables for comparison.No advance, but my pictures are further up this thread.

Chris Warren

Member

Has anyone actually tried lubricating the cables?

audifan

A2OC Donor

No progress that I am aware of. Before condemning the cables you will need to make sure the problem is not with the selector tower / brackets nor the gear stick pivot ball area. Disconnect from the selector tower and ensure that moves correctly without slop and check the brackets are secure and the pivot bell crank bushing is not worn out. Then disconnect the cables from the base of the gear stick and ensure the range of movement is available without resistance and the stick self centres. now move each cable in turn from where you disconnected at the base of the gear stick to see if they are stiff or notchy in movement. The cables can be damaged when the gearbox is removed by someone bending them back on themselves instead of supporting them from the expansion tank hose.

Chris Warren

Member

My TDi gear change was horrible. I suspected the cables could be shot until I had a close look at the gearbox end. The bearing in the selector mechanism was badly worn so I disconnected the cables from the gearbox end and tried the gearstick. It all felt pretty good. Anyway, after removing the box, changing the bearing and seal, the clutch, fresh oil, bleeding the hydraulics and cleaning and lubricating the ball and socket at the base of the gearstick I now have a really positive and smooth gear change. So don't always assume the cables are shot.No progress that I am aware of. Before condemning the cables you will need to make sure the problem is not with the selector tower / brackets nor the gear stick pivot ball area. Disconnect from the selector tower and ensure that moves correctly without slop and check the brackets are secure and the pivot bell crank bushing is not worn out. Then disconnect the cables from the base of the gear stick and ensure the range of movement is available without resistance and the stick self centres. now move each cable in turn from where you disconnected at the base of the gear stick to see if they are stiff or notchy in movement. The cables can be damaged when the gearbox is removed by someone bending them back on themselves instead of supporting them from the expansion tank hose.

PlasticMac

Member

Following on from a conversation with @chumsofmanutd at Saturdays End of Season Meal, I hope this can be moved on. WOM have cars that will, hopefully, serve to get cable dimensions, and end terminations. I've been in touch with Cable-Tec today, so  .

.

Mac.

Mac.

Chris Warren

Member

Would be fantastic if an alternative supplier could remanufacture them. I’d be happy to contribute.My mums car is in with WOM now, from what i can gather they have sent off my cables to see if anything can be done.

PlasticMac

Member

Here's the reply from Cable-Tec:

"I gathered two sets of parts that will be fairly universal while working out how long the travel and reaches should be at the gearbox and lever ends. The rods and guide tubes will have to be cut to accommodate the lengths of the ends that mount to vehicle while ensuring the correct stroke is achieved and sometimes we drill the bulkheads so that the rods can bottom a little further down if needed. The pins in the ball joints can be removed and should clip onto the existing parts on the vehicle"

Sounds promising, also an illustration of how the new cables might fit to the existing parts, if re-using them is OK.

Could @chumsofmanutd have a look, and let me know if it matches a real tower and gearbox.

Mac.

"I gathered two sets of parts that will be fairly universal while working out how long the travel and reaches should be at the gearbox and lever ends. The rods and guide tubes will have to be cut to accommodate the lengths of the ends that mount to vehicle while ensuring the correct stroke is achieved and sometimes we drill the bulkheads so that the rods can bottom a little further down if needed. The pins in the ball joints can be removed and should clip onto the existing parts on the vehicle"

Sounds promising, also an illustration of how the new cables might fit to the existing parts, if re-using them is OK.

Could @chumsofmanutd have a look, and let me know if it matches a real tower and gearbox.

Mac.

chumsofmanutd

A2OC Donor

Hi guys,

Yes we're working on a solution to the gear cable issues with Cable-Tec at the moment. We'll keep you updated on progress.

Cheers

Rob WOM

Yes we're working on a solution to the gear cable issues with Cable-Tec at the moment. We'll keep you updated on progress.

Cheers

Rob WOM