depronman

A2OC Donor

For some time I have missed the heated seats that I have in my Focus CC, there is nothing quite like top down motoring when the temp is 5 deg C on a dry day, with the heated seats and the heater wafting hot air around your body, with the rear wind deflector up and windows up there is really very little draft in the cabin.

As my daily commute to work is 8 miles each way and the TDI takes around 4 miles to get to an engine temperature where the heater is blowing warm I figured that heated seats in the A2 would be a really good idea.

I have recently upgraded to black sports seats with matching rear bench seat, ideally these sports seats would have been heated, but I believe that is very rare. I'm not a fan of full leather seats so that rules out the Mk1 TT heated leather seats, so I decided to DIY heating pads into the sports seats.

The kit I bought had 4 heater pads, the loom, control box and relay, fuse holder and heater control switch.

I chose this particular kit because the control switch looked very Audi ish, I also bought a pair of Audi A4 heated seat switches, but it turns out that the wiring and control system is very different on the Audi heated seats, so rigging up the Audi switches was going to be a big challenge.

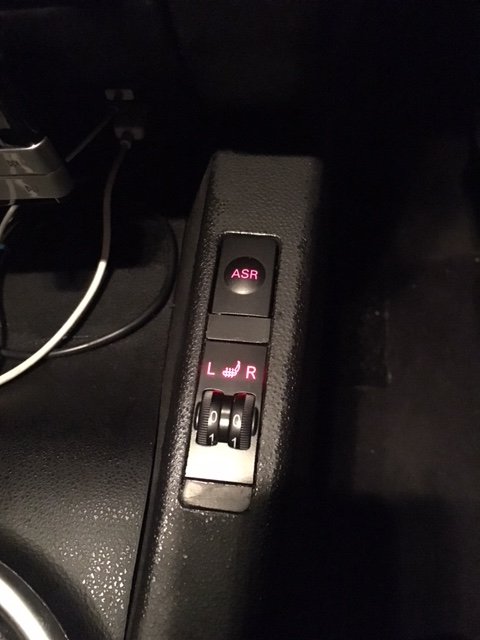

I set up the heated seat kit in the bench and was rather pleased with the look and feel of the control switch, it had a nice red glow when the seats where on, but the lighting circuit proved to be less good in that it was a terrible neon blue. Taking the switch apart the blue was provided by 2 surface mount LED's, these were changed for red surface mount LED's which made the switch look very OEM and matched the remains of the A2 interior very well.

The switch fascia was a little too wide for the location I had in mind which was the blanking plate just to the rear of the ASR switch. I have a hybrid 2Din dash with manual heater controls, so the normal heated heat location at the LH and RH side of the climate control panel is not available to be, nor is the smaller cubby hole.

The switch fascia was sanded to suit the opening in the centre 'console wing', a 3D part was printed to slot into the space in the wing (after the bridging web was removed) and super glued into place, the switch then mounts and clips into the 3D printed mount and the switch fascia fits like the ASR switch. There was however a gap at the front and between the heated seat switch and the ASR switch, so a couple of 3D printed infill pieces were made and sprayed matt black. The owl switch assy looks very OEM and I am more than pleased with how it came out

Fitting the heater pads into the sports seats was a challenge in itself. I have never had seats apart before, but I followed a guide found on A2OC and within 1/2 an hour the seats were split apart and the base cover was being removed, now those hog rings are something else, but once I figured out how to remove them it took about 3/4 hour to remove the seat cover, once removed the foam base needed some repair on the bolster, I had an old foam insert out of an SE seat that was cut up to repair the Sports seat bolster.

The Heater pad was then stuck to the foam base with the supplied double sided tape, the heater pad needed to follow the foam base, but does so easily. Cut outs need to be made to allow the centre hog rings to pass through the heater pads, you need to choose your position to do this such that the element is not cut. The rear of the foam insert needs a cut extending forward about 2 inches to accommodate the heater pad cabling. There was 2.5" wide sticky silver foil to attached to either end of the pad to secure it to the foam insert.

It took about an hour to re attach the seat cover using the hog rings, then clip the seat cover to the seat base - one done 3 to go

The seat back was a puzzle until I realised how to get the cloth out of the back, it is VERY tight and takes a LOT of teasing to get it out.

Once out the air bag unit is removed by removing the 3 nuts and the seat back cover can be removed as per the base cover by removing the hog rings. The foam was good so no repairs needed, heater pads stuck in place and seat back cover refitted, I now hatted the hog rings - and still another seat to do !!!

The heater pads have white connectors, which fit nicely side by side, so I 3D printed a block to hose the two connectors and fit into the plastic connector housing under the seat, so it fits like the oem heated seat connectors would.

The other seat was stripped and heater pads fitted as above.

The wiring loom was installed against the car floor in the middle of the centre console, the power being picked up from the main batter feed in the passenger under foot compartment, earth from the aluminium structure under the centre console, only two wires left, one for ignition live picked up from fuse 38 in the main fuse box and the lights picked up from one of the 10amp fuses. loom was run down the centre console and out to the two seats with the other cars loom for the lumber support and air bags.

Seats refitted in car and all connector reconnect, vagcom to turn off the airbag light on dash (I tuned ignition on to test heated seat loom with no seats connected to airbag looms)

Finally sat in drivers seat, started engine and turned seat heating on to 1 which provided very light heating, 2, 3 ,4 progressively more heat and 5 even more. I suspect that 5 would not be used very often or for very long, but is nice and warm. The heating is very uniform and heats all of the seat bottom and 2/3rds of the back.

To say I am more than happy with the weekends work is a massive understatement I am totally delighted.

I also fitted a new Pioneer 'carplay' 2Din head unit, but that is another story for another day (enough to say that my A2 now as voice command control for the Audi / navigation system, really rather snazzy)

As my daily commute to work is 8 miles each way and the TDI takes around 4 miles to get to an engine temperature where the heater is blowing warm I figured that heated seats in the A2 would be a really good idea.

I have recently upgraded to black sports seats with matching rear bench seat, ideally these sports seats would have been heated, but I believe that is very rare. I'm not a fan of full leather seats so that rules out the Mk1 TT heated leather seats, so I decided to DIY heating pads into the sports seats.

The kit I bought had 4 heater pads, the loom, control box and relay, fuse holder and heater control switch.

I chose this particular kit because the control switch looked very Audi ish, I also bought a pair of Audi A4 heated seat switches, but it turns out that the wiring and control system is very different on the Audi heated seats, so rigging up the Audi switches was going to be a big challenge.

I set up the heated seat kit in the bench and was rather pleased with the look and feel of the control switch, it had a nice red glow when the seats where on, but the lighting circuit proved to be less good in that it was a terrible neon blue. Taking the switch apart the blue was provided by 2 surface mount LED's, these were changed for red surface mount LED's which made the switch look very OEM and matched the remains of the A2 interior very well.

The switch fascia was a little too wide for the location I had in mind which was the blanking plate just to the rear of the ASR switch. I have a hybrid 2Din dash with manual heater controls, so the normal heated heat location at the LH and RH side of the climate control panel is not available to be, nor is the smaller cubby hole.

The switch fascia was sanded to suit the opening in the centre 'console wing', a 3D part was printed to slot into the space in the wing (after the bridging web was removed) and super glued into place, the switch then mounts and clips into the 3D printed mount and the switch fascia fits like the ASR switch. There was however a gap at the front and between the heated seat switch and the ASR switch, so a couple of 3D printed infill pieces were made and sprayed matt black. The owl switch assy looks very OEM and I am more than pleased with how it came out

Fitting the heater pads into the sports seats was a challenge in itself. I have never had seats apart before, but I followed a guide found on A2OC and within 1/2 an hour the seats were split apart and the base cover was being removed, now those hog rings are something else, but once I figured out how to remove them it took about 3/4 hour to remove the seat cover, once removed the foam base needed some repair on the bolster, I had an old foam insert out of an SE seat that was cut up to repair the Sports seat bolster.

The Heater pad was then stuck to the foam base with the supplied double sided tape, the heater pad needed to follow the foam base, but does so easily. Cut outs need to be made to allow the centre hog rings to pass through the heater pads, you need to choose your position to do this such that the element is not cut. The rear of the foam insert needs a cut extending forward about 2 inches to accommodate the heater pad cabling. There was 2.5" wide sticky silver foil to attached to either end of the pad to secure it to the foam insert.

It took about an hour to re attach the seat cover using the hog rings, then clip the seat cover to the seat base - one done 3 to go

The seat back was a puzzle until I realised how to get the cloth out of the back, it is VERY tight and takes a LOT of teasing to get it out.

Once out the air bag unit is removed by removing the 3 nuts and the seat back cover can be removed as per the base cover by removing the hog rings. The foam was good so no repairs needed, heater pads stuck in place and seat back cover refitted, I now hatted the hog rings - and still another seat to do !!!

The heater pads have white connectors, which fit nicely side by side, so I 3D printed a block to hose the two connectors and fit into the plastic connector housing under the seat, so it fits like the oem heated seat connectors would.

The other seat was stripped and heater pads fitted as above.

The wiring loom was installed against the car floor in the middle of the centre console, the power being picked up from the main batter feed in the passenger under foot compartment, earth from the aluminium structure under the centre console, only two wires left, one for ignition live picked up from fuse 38 in the main fuse box and the lights picked up from one of the 10amp fuses. loom was run down the centre console and out to the two seats with the other cars loom for the lumber support and air bags.

Seats refitted in car and all connector reconnect, vagcom to turn off the airbag light on dash (I tuned ignition on to test heated seat loom with no seats connected to airbag looms)

Finally sat in drivers seat, started engine and turned seat heating on to 1 which provided very light heating, 2, 3 ,4 progressively more heat and 5 even more. I suspect that 5 would not be used very often or for very long, but is nice and warm. The heating is very uniform and heats all of the seat bottom and 2/3rds of the back.

To say I am more than happy with the weekends work is a massive understatement I am totally delighted.

I also fitted a new Pioneer 'carplay' 2Din head unit, but that is another story for another day (enough to say that my A2 now as voice command control for the Audi / navigation system, really rather snazzy)