You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My A2 doesn't like the cold

- Thread starter sco

- Start date

depronman

A2OC Donor

Thanks Paul I'll have a think about the VW Tools and Vag Commander - I take it Win Xp is a necessity as I don't have access to that version of Windows.

I'm going to check the 'torsion' value and few other things at the weekend when I have some time and some daylight.

Simon.

VW Tools will only run under WinXP, VAGCOM under Win732 bit for sure, may even be later versions

I have just got a dual core intel based laptop and installed WinXp on it just for car diagnostics software, it will not be used with anything else, no internet etc

XP seems to be the defacto std for car diagnostic software, plus on a 5+ year old laptop it is mega fast

BTW VW Tools needs the VAG COMMANDER cable to work, not the same cable as VAGCOM/VCDS, but with VAG COMMANDER you can access the SKC amongst other things

sco

A2OC Donor

Still investigating this issue - tried doing the neat diesel purge routine this morning to hopefully clean the injectors - too early to tell if this has made any difference but the forecast is for a cold snap next week so that should confirm one way or the other. The residual in the jam jar was very dark yellow by the end but with no obvious solids.

The outlawed and unloved Jigsaw has suggested that it could be a symptom of the head gasket failing between cylinders but I need to get a compression tester before I can investigate that avenue.

Simon.

The outlawed and unloved Jigsaw has suggested that it could be a symptom of the head gasket failing between cylinders but I need to get a compression tester before I can investigate that avenue.

Simon.

sco

A2OC Donor

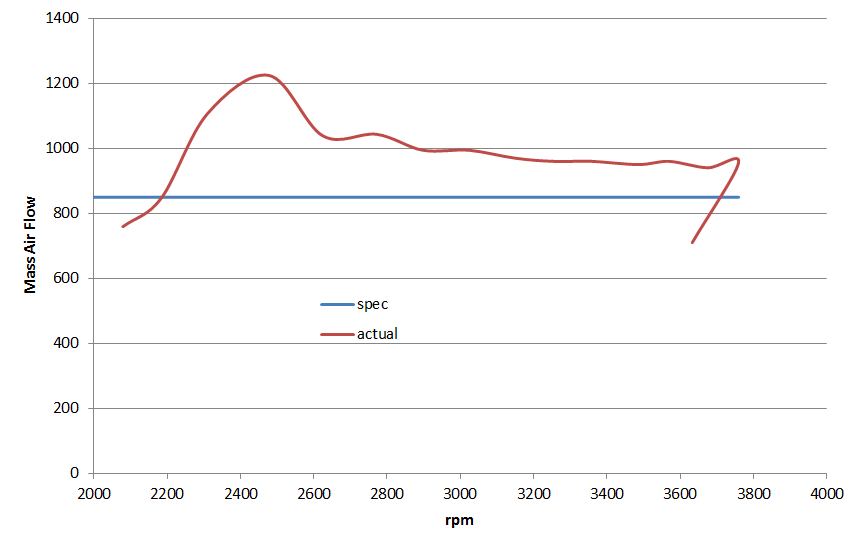

Still suffering with this rough running in the cold weather - APS in Brackley took a look yesterday and said yes it does seem a bit rough but can't find anything wrong (no charge). Logged the MAF on the way home which sort of looks reasonable;

APS couldn't check the cylinder compression so still need to order a tester to see if the gasket has failed between cylinders.

Simon.

APS couldn't check the cylinder compression so still need to order a tester to see if the gasket has failed between cylinders.

Simon.

damadgeruk

A2OC Donor

What did you use to log the MAF? I haven't spent much time on diagnostics recently though have been meaning to check what is accessible on torque pro(android) using my Elm Bluetooth obd plug.Still suffering with this rough running in the cold weather - APS in Brackley took a look yesterday and said yes it does seem a bit rough but can't find anything wrong (no charge). Logged the MAF on the way home which sort of looks reasonable;

View attachment 36975

APS couldn't check the cylinder compression so still need to order a tester to see if the gasket has failed between cylinders.

Simon.

dieselfan

A2OC Donor

SCO - have you checked out all the mechanical potentials? (since i do not have VCDS nor know how to use it I do the manual checks first...)

From how I understand your descriptions:

This could to my opinion be related to dieselfilter, air in fuel system or restriction in fuel system.

I would have checked the following first since it will not show on a VCDS scan.

Dieselfilter life depends first of all on what you shall filter... it is enough to fill one tank from a "polluted" petrol station and even a brand new filter is clogged.... then the Tandempump will have to work hard and will suffer to feed the PDs and then you get rough running engine.

Hope this can be to some help. My apologies for terminology mistakes and strange grammar/spelling... I still suffer from brilliant sea view from the classroom I was supposed to learn English language in (many thanks to google translate)

(many thanks to google translate)

From how I understand your descriptions:

- Runs rough

- Runs fine on idle

- Poor acceleration

- Starts easily

- Escalate when temperature drops

This could to my opinion be related to dieselfilter, air in fuel system or restriction in fuel system.

I would have checked the following first since it will not show on a VCDS scan.

- Visual check for leaks of all diesel lines including connectors and caps. (remember if ANY sign of diesel leak there will always come air in...)

- Visual check for crushed, bent fuel lines og diesel cooler with dents or damages that could result in reduced fuel flow.

- Change dieselfilter if you are in any doubt wrt condition of filter or passed 20.000miles/30000km

- If your 2005 neither is equipped with a feed pump in the tank, a lot is depending on the tandem pump. I connect a piece of clear tube between Tandempump outlet and the feed line for PDs. Then I set up a GoPro to surveil the piece of clear hose and take a 10min test run. If you do not see any bobbles after 5 min I would say; make the VCDS ready...

- If you can see on the video that the hose get sucked flat'ish I would recommend to check further the Tandempump and fuel system. That is an indication of insuffisient flow.

Dieselfilter life depends first of all on what you shall filter... it is enough to fill one tank from a "polluted" petrol station and even a brand new filter is clogged.... then the Tandempump will have to work hard and will suffer to feed the PDs and then you get rough running engine.

Hope this can be to some help. My apologies for terminology mistakes and strange grammar/spelling... I still suffer from brilliant sea view from the classroom I was supposed to learn English language in

sco

A2OC Donor

SCO - have you checked out all the mechanical potentials? (since i do not have VCDS nor know how to use it I do the manual checks first...)

From how I understand your descriptions:

My immediate thought is that your problem occur when you both need more fuel and the temperature is low.

- Runs rough

- Runs fine on idle

- Poor acceleration

- Starts easily

- Escalate when temperature drops

This could to my opinion be related to dieselfilter, air in fuel system or restriction in fuel system.

I would have checked the following first since it will not show on a VCDS scan.

Over here it happens on A2s and others with diesel-coolers underneath the car that they get knocked flat by ice-blocks during wintertime and during off-road driving. If no major leak, the symptoms are as you describe.

- Visual check for leaks of all diesel lines including connectors and caps. (remember if ANY sign of diesel leak there will always come air in...)

- Visual check for crushed, bent fuel lines og diesel cooler with dents or damages that could result in reduced fuel flow.

- Change dieselfilter if you are in any doubt wrt condition of filter or passed 20.000miles/30000km

- If your 2005 neither is equipped with a feed pump in the tank, a lot is depending on the tandem pump. I connect a piece of clear tube between Tandempump outlet and the feed line for PDs. Then I set up a GoPro to surveil the piece of clear hose and take a 10min test run. If you do not see any bobbles after 5 min I would say; make the VCDS ready...

- If you can see on the video that the hose get sucked flat'ish I would recommend to check further the Tandempump and fuel system. That is an indication of insuffisient flow.

Dieselfilter life depends first of all on what you shall filter... it is enough to fill one tank from a "polluted" petrol station and even a brand new filter is clogged.... then the Tandempump will have to work hard and will suffer to feed the PDs and then you get rough running engine.

Hope this can be to some help. My apologies for terminology mistakes and strange grammar/spelling... I still suffer from brilliant sea view from the classroom I was supposed to learn English language in(many thanks to google translate)

Dieselfan you raise some good points thank you and your English is perfectly understandable.

I'll have a good look for leaks this weekend and I have a new fuel filter to hand so as you say it makes sense to change this, thanks again,

Simon.

sco

A2OC Donor

The temp log looks normal so my faulty fuel temp sensor theory is highly unlikely

Cheers Spike

Thanks Spike - did wonder if the difference to the coolant temperature was right or not.

Simon.

depronman

A2OC Donor

Simon,

I can't remember if you bought one of my fuel filter screws, if not and you have the later fuel filter (black plastic housing type) then be VERY careful removing and refitting the drain screw. If you do happen to break it I have one left ATM, but will try to get some more made tomorrow (looks like I'm spending another day in front of my Boxford lathe )

)

Cheers,

Paul

I can't remember if you bought one of my fuel filter screws, if not and you have the later fuel filter (black plastic housing type) then be VERY careful removing and refitting the drain screw. If you do happen to break it I have one left ATM, but will try to get some more made tomorrow (looks like I'm spending another day in front of my Boxford lathe

Cheers,

Paul

depronman

A2OC Donor

Cheers Paul for the reminder about the drain screw,. I was thinking about making a ghetto service tool that would allow access to the main hex without having to disturb the drain screw. Just an idea at the moment nothing more.

Simon.

Hi Simon. That only solves half of the problem. The screw is there to drain water out of the filter housing as well as drain fuel when replacing the filter. Your idea will work for the filter change but not for the water drain

The Audi idea of the drain screw was good just poorly executed. My aluminium screw rectifies this

Cheers. Paul

Sent from my iPhone using Tapatalk

sco

A2OC Donor

Changed the fuel filter today - it was black and the filter base was full of tar like crud so I'm hopeful that might be some or all of the issue. Quick test drive showed maybe slightly better but it is warmer today so not completely convinced - will do a more thorough test next week. (No drain plugs were harmed in this operation  )

)

Paul - understood on the drain plug is there to drain water but hands up who has regularly done that? Do you think any water in the fuel might corrode your aluminium screw long term?

Simon.

Paul - understood on the drain plug is there to drain water but hands up who has regularly done that? Do you think any water in the fuel might corrode your aluminium screw long term?

Simon.