Little Dog

A2OC Donor

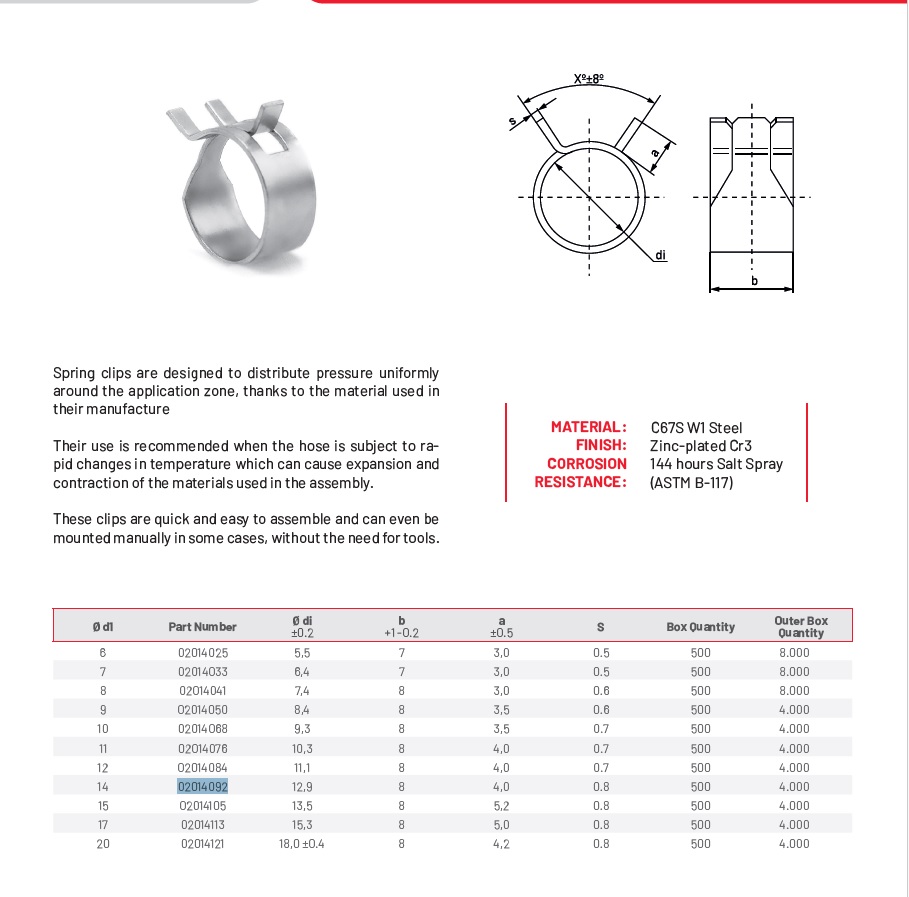

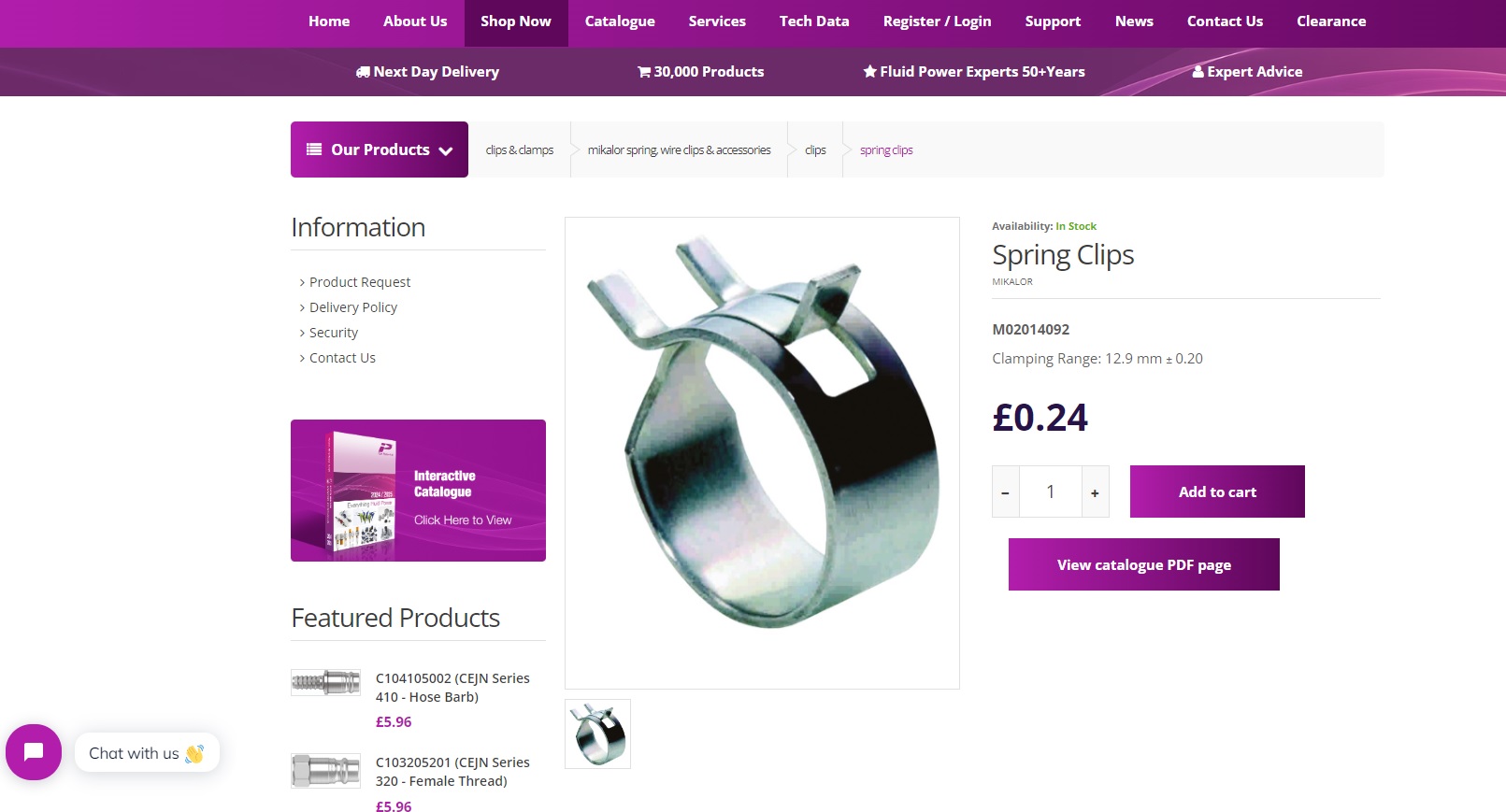

@rotifer I no longer buy VAG clips. I get a spec and part number here, https://mikalorcompany.com/ .

This may be the clip you and I will be looking for but I wouldn't commit without measuring pipes

I then search for an online supplier, I usually find them on eBay but not on this occasion.

I don't know if this is the correct clip or what P&P will cost but with the number I need I think I will save a few £.

One of the reservations I have about this job is that the pipe is likely to have lost its elasticity under the clip and replacing clips will introduce leaks and cause starting problems.

Edit, I see you have already discovered Mikalor, I'll leave this post, may help others.

This may be the clip you and I will be looking for but I wouldn't commit without measuring pipes

I then search for an online supplier, I usually find them on eBay but not on this occasion.

I don't know if this is the correct clip or what P&P will cost but with the number I need I think I will save a few £.

One of the reservations I have about this job is that the pipe is likely to have lost its elasticity under the clip and replacing clips will introduce leaks and cause starting problems.

Edit, I see you have already discovered Mikalor, I'll leave this post, may help others.

Last edited: