You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PDC retrofit

- Thread starter simufly

- Start date

2work

Well Known Member

Morning Simon,

I’m finally getting round to removing the rear bumper on Project EUD by the Weekend to conduct this very retrofit. I will certainly be able to put something together one evening afterwards. I do have the Kufatec PDC loom installation PDF which can be used also. It’s not the exact way I’ll be doing it myself so probably best to wait until I’ve completed my retrofit and I’ll helpfully share what I know.

Kind regards,

Tom

I’m finally getting round to removing the rear bumper on Project EUD by the Weekend to conduct this very retrofit. I will certainly be able to put something together one evening afterwards. I do have the Kufatec PDC loom installation PDF which can be used also. It’s not the exact way I’ll be doing it myself so probably best to wait until I’ve completed my retrofit and I’ll helpfully share what I know.

Kind regards,

Tom

simufly

A2OC Donor

YepIs PDC parking distance control?

2work

Well Known Member

Hello again Simon,

Just about to head into a meeting but thought is right to share the information that I currently have to hand to assist you and others. Attached are 2x PDF documents, one is the Kufatrec installation instructions which you can download from their website, the other is a breakout of the necessary pages from the EWD associated with the PDC pinouts. It's exactly what I've used to bring my knowledge up to the required standard to conduct this particular retrofit. Both the EWD and Kufatec instructions mention taking feeds from the region of the instrument cluster, these specific feeds can be obtained from elsewhere within the vehicle which I'm sure are mentioned on a thread somewhere on here. I personally know where the feeds can be taken from but trying to locate the informative thread for in question for reference.

I should be able to provide a much clearer reply once I get the tools out this weekend when I'll take a few pictures for you Sir.

Kind regards,

Tom

Just about to head into a meeting but thought is right to share the information that I currently have to hand to assist you and others. Attached are 2x PDF documents, one is the Kufatrec installation instructions which you can download from their website, the other is a breakout of the necessary pages from the EWD associated with the PDC pinouts. It's exactly what I've used to bring my knowledge up to the required standard to conduct this particular retrofit. Both the EWD and Kufatec instructions mention taking feeds from the region of the instrument cluster, these specific feeds can be obtained from elsewhere within the vehicle which I'm sure are mentioned on a thread somewhere on here. I personally know where the feeds can be taken from but trying to locate the informative thread for in question for reference.

I should be able to provide a much clearer reply once I get the tools out this weekend when I'll take a few pictures for you Sir.

Kind regards,

Tom

Attachments

Oskar

A2OC Donor

I have just completed this task, so I offer some learnings and comments, rather than a specific 'How To'.

The instructions from @2work in the preceding post, along with other PDC threads, and the usual on-line videos etc provides plenty of info in relation to a full set of instructions, albeit only on the 'obvious' elements.

From my projects, below are a few pointers that, along with the other information, may make it easier for anyone wanting to attempt this valuable upgrade.

1- Hardware

2- Loom Install

3- Bumper removal and Sensor Loom

4- Sensor Install

5- Coding

1- Hardware

For this project, you will need

a controller module, likely from our club breakers, or ebay. I think any that start with 8Z... will likely do, as they are all pretty much the same and can be coded for A2. Look for Audi in the early 2000's, and that important item number. They start at £10!

A Loom from the module into the car, for power etc. This should have the correct 16 pin connector, which is the largest of the 3 into the module, likely green. It will have the 2 pin for the speaker also.

A loom to the sensors, from the module going into the rear bumper. This should have the correct 12 pin connector to the module.

A speaker (£7 new, on ebay).

...and of course, 4 sensors and corresponding mounts, again ebay.

Note, there are a few sizes, so you need to decide which sensors you wish to use, then get the correct mounts, and then make the correct size holes.

I used 23mm sensors, with the oblong centre, as I believe these are the same as factory fit. Round ones are fine, and smaller, as long as they are VAG compatible. Do some research, and check those measurements!

The looms are available from Kufatec direct, or from them via eBay (safer for possible Brexit issues....). Timmus may also be able to sell you them, but that may be old news....

It is important the sensor loom has a correct size grommet, to replace the one you will detach, to avoid any water going into the car. You could bodge the existing grommet, but that is not recommended. Any decent loom should have a grommet attached.

2- Loom install

The module should be installed in a very small cavity under the polystyrene block that holds the triangle/first aid kit.

Therefore, you will need to take off the left hand boot interior liner, and associated bits. There is quite a bit here, but have a look for various posts, manuals and videos on how to do this, and remember where all the bits go back!

Once you have taken off all the trim, you need to feed the loom up the lefthand side of the car, on the sill (follow the main loom already present), into the passenger footwell, then into the centre console, and up behind the pedals, to get to the instrument cluster.

My loom was not actually long enough except for the 3 wires which need to connect to the instruments, however I always intended to use alternative connections for the remaining wires.

The 3 I used to get to the instruments are,

CAN high

CAN low

K-line (diagnostics)

(also in this group is Gala (speed) which is not necessary, and can be taped to safety anywhere).

The remainder I changed to,

Earth - Passenger A pillar. There is a good point in there.

Constant 12v - A sub-fusebox in the passenger footwell, or any other constant permanent 12v supply you wish.

Ignition 12v - I managed to find another Black/Blue supply in the passenger A pillar, so just connected to that.

Reverse light - This is short, and can only be connected to the + for the reverse light on the left. I think it is Pin 1 on the connector to the bulb rack (Red/ Blue stripe?)

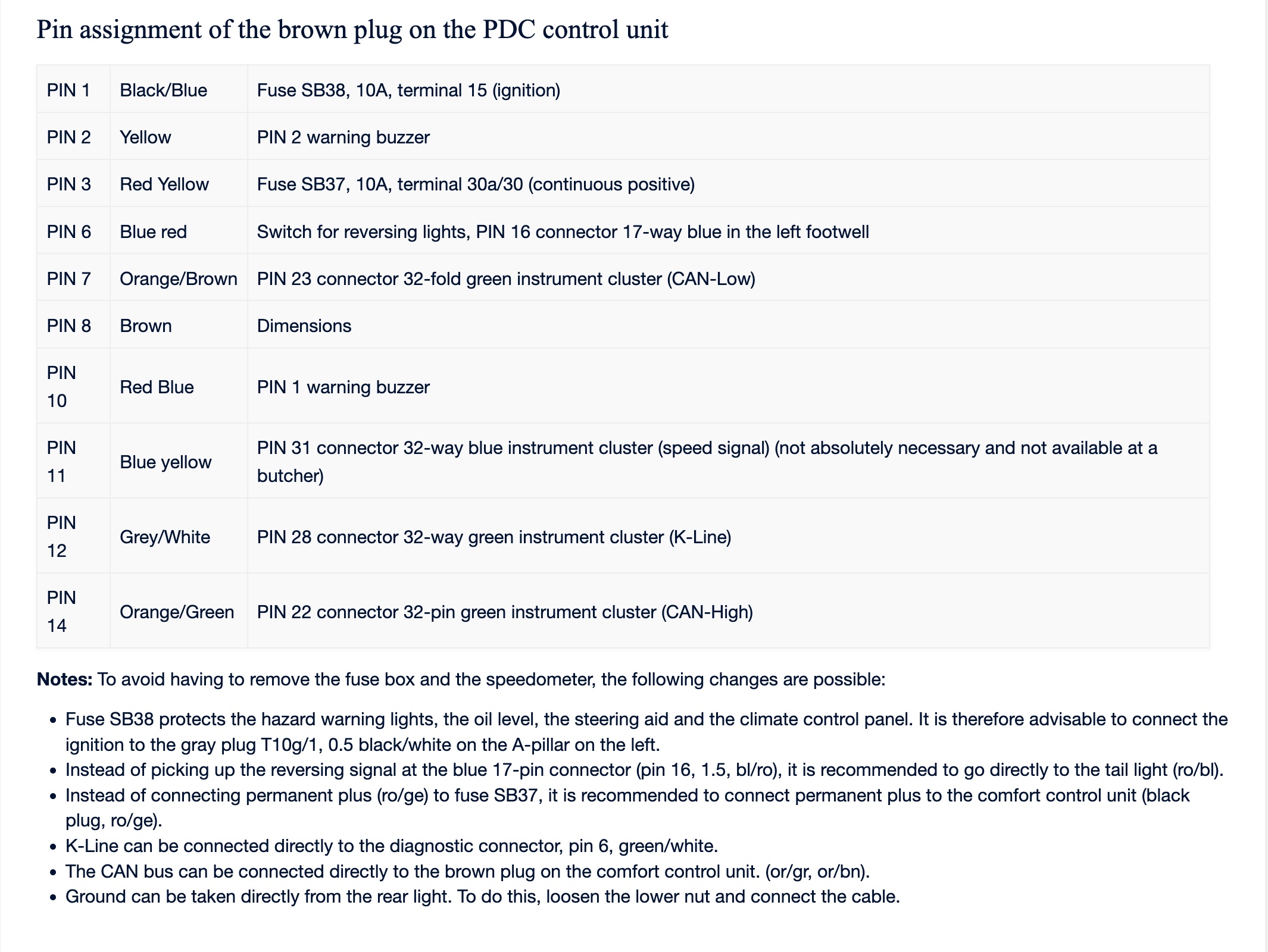

Have a look at this site and translation, which I found very useful. Not sure about the accuracy of the first column, but the notes especially are useful.

wiki.a2-freun.de

wiki.a2-freun.de

My loom came with no colours (all wires are white), but the last few inches of each have the name of the wire, and usefully, the pin number etc, so for example, the k-line wire had 'Diagnostics T32/28' or suchlike, so I could connect it easily.

This is very useful for me, as I am colourblind, and often have no idea of what colour wires are......or connectors, or even cars!

You may need to do a bit of homework here, and make changes as it suits your tools, capability and preferences. Some may not wish to open the instrument cluster, and connect to the CCU. I certainly had no desire to open the fusebox.......

For wires which need spliced into another cable, I used these. Cheap on ebay, and a lot easier than soldering etc, but perhaps not the best long term. You just need to do what you wish.

In my car, I have no Pin 6 on my OBD connector (2001, pre CANBUS for radio), so took the k-line to the instrument cluster.

There is quite a bit of work laying the loom, connecting it all up and ensuring the module and speaker etc are all mounted correctly. The module needs to have the connectors on the bottom of the module, with all cables tucked away, or the poly block will not fit back in correctly. See photo.

3- Bumper removal and sensor loom

This was the most difficult part for me. Follow the instructions (elsewhere) for bumper removal, but the bits I could have done knowing about are,

There are 2 screws you need to access after part-detaching the inner liner of the rear wheels. These are the most 'sunken' and difficult to see and access, of the many screws you will see. Just these 2 need to be taken out (not just loosened). See photo with yellow arrows (same on each side).

Then, you need to pull the side flap of the bumper out away from the car, so it comes out of the slot and clips, as shown in the photo. You may need to lever it out gently, without scratches!

Note the 2 screw positions. This shows why you have the remove the screws, to allow the holed tabs in the bumper to come out of the slots.

I had 3 tabs on my bumper, but only 2 screws through the slot. You may have 3.....

The rest of the bumper is as per other instructions - easy really.

You will then see the grommet on the lower left, for the loom to go through.

Lay that loom as it appears obvious. I tied mine with loose cable ties just to keep it all tidy.

4- Sensor Install.

Once you have carefully selected your sensors and mounts, you need to put the appropriate holes in your bumper.

I used a sheet metal punch, which created a perfectly sized hole and an excellent finish. I can only recommend this type of hole, as opposed to a drill etc. There are a couple of post on this site detailing this process.

I supplemented the double sided tape on my sensor mounts with a treatement all round with a hot glue gun. This is mainly to prevent water ingress, but may also help with retention.

5- Coding

Don't forget this part, especially if you are not certain your module came from an A2.

Using VCDS or VCDS lite, select module 76 (under Electronics 1 tab).

The instructions from Ross-Tech are here. http://wiki.ross-tech.com/wiki/index.php/Audi_A2_(8Z)_Parking_Aid

00102 is the code to use.

Mine was beeping, completely randomly until I coded it correctly.

This is a great project, but does need some research and decision making, and some 'flexibility' from the instructions depending on your situation and confidence.

It will take some time, just to sort the trim and connections, but is well worth it. Don't be afraid of the instrument cluster, but make sure you have taken instructions from somewhere beforehand.

There are plenty of associated posts here, and elsewhere (in German!), so it is worthwhile spending many hours researching advance.

Good luck!

Matt

The instructions from @2work in the preceding post, along with other PDC threads, and the usual on-line videos etc provides plenty of info in relation to a full set of instructions, albeit only on the 'obvious' elements.

From my projects, below are a few pointers that, along with the other information, may make it easier for anyone wanting to attempt this valuable upgrade.

1- Hardware

2- Loom Install

3- Bumper removal and Sensor Loom

4- Sensor Install

5- Coding

1- Hardware

For this project, you will need

a controller module, likely from our club breakers, or ebay. I think any that start with 8Z... will likely do, as they are all pretty much the same and can be coded for A2. Look for Audi in the early 2000's, and that important item number. They start at £10!

A Loom from the module into the car, for power etc. This should have the correct 16 pin connector, which is the largest of the 3 into the module, likely green. It will have the 2 pin for the speaker also.

A loom to the sensors, from the module going into the rear bumper. This should have the correct 12 pin connector to the module.

A speaker (£7 new, on ebay).

...and of course, 4 sensors and corresponding mounts, again ebay.

Note, there are a few sizes, so you need to decide which sensors you wish to use, then get the correct mounts, and then make the correct size holes.

I used 23mm sensors, with the oblong centre, as I believe these are the same as factory fit. Round ones are fine, and smaller, as long as they are VAG compatible. Do some research, and check those measurements!

The looms are available from Kufatec direct, or from them via eBay (safer for possible Brexit issues....). Timmus may also be able to sell you them, but that may be old news....

It is important the sensor loom has a correct size grommet, to replace the one you will detach, to avoid any water going into the car. You could bodge the existing grommet, but that is not recommended. Any decent loom should have a grommet attached.

2- Loom install

The module should be installed in a very small cavity under the polystyrene block that holds the triangle/first aid kit.

Therefore, you will need to take off the left hand boot interior liner, and associated bits. There is quite a bit here, but have a look for various posts, manuals and videos on how to do this, and remember where all the bits go back!

Once you have taken off all the trim, you need to feed the loom up the lefthand side of the car, on the sill (follow the main loom already present), into the passenger footwell, then into the centre console, and up behind the pedals, to get to the instrument cluster.

My loom was not actually long enough except for the 3 wires which need to connect to the instruments, however I always intended to use alternative connections for the remaining wires.

The 3 I used to get to the instruments are,

CAN high

CAN low

K-line (diagnostics)

(also in this group is Gala (speed) which is not necessary, and can be taped to safety anywhere).

The remainder I changed to,

Earth - Passenger A pillar. There is a good point in there.

Constant 12v - A sub-fusebox in the passenger footwell, or any other constant permanent 12v supply you wish.

Ignition 12v - I managed to find another Black/Blue supply in the passenger A pillar, so just connected to that.

Reverse light - This is short, and can only be connected to the + for the reverse light on the left. I think it is Pin 1 on the connector to the bulb rack (Red/ Blue stripe?)

Have a look at this site and translation, which I found very useful. Not sure about the accuracy of the first column, but the notes especially are useful.

Einparkhilfe – A2-Freun.de Wiki

My loom came with no colours (all wires are white), but the last few inches of each have the name of the wire, and usefully, the pin number etc, so for example, the k-line wire had 'Diagnostics T32/28' or suchlike, so I could connect it easily.

This is very useful for me, as I am colourblind, and often have no idea of what colour wires are......or connectors, or even cars!

You may need to do a bit of homework here, and make changes as it suits your tools, capability and preferences. Some may not wish to open the instrument cluster, and connect to the CCU. I certainly had no desire to open the fusebox.......

For wires which need spliced into another cable, I used these. Cheap on ebay, and a lot easier than soldering etc, but perhaps not the best long term. You just need to do what you wish.

In my car, I have no Pin 6 on my OBD connector (2001, pre CANBUS for radio), so took the k-line to the instrument cluster.

There is quite a bit of work laying the loom, connecting it all up and ensuring the module and speaker etc are all mounted correctly. The module needs to have the connectors on the bottom of the module, with all cables tucked away, or the poly block will not fit back in correctly. See photo.

3- Bumper removal and sensor loom

This was the most difficult part for me. Follow the instructions (elsewhere) for bumper removal, but the bits I could have done knowing about are,

There are 2 screws you need to access after part-detaching the inner liner of the rear wheels. These are the most 'sunken' and difficult to see and access, of the many screws you will see. Just these 2 need to be taken out (not just loosened). See photo with yellow arrows (same on each side).

Then, you need to pull the side flap of the bumper out away from the car, so it comes out of the slot and clips, as shown in the photo. You may need to lever it out gently, without scratches!

Note the 2 screw positions. This shows why you have the remove the screws, to allow the holed tabs in the bumper to come out of the slots.

I had 3 tabs on my bumper, but only 2 screws through the slot. You may have 3.....

The rest of the bumper is as per other instructions - easy really.

You will then see the grommet on the lower left, for the loom to go through.

Lay that loom as it appears obvious. I tied mine with loose cable ties just to keep it all tidy.

4- Sensor Install.

Once you have carefully selected your sensors and mounts, you need to put the appropriate holes in your bumper.

I used a sheet metal punch, which created a perfectly sized hole and an excellent finish. I can only recommend this type of hole, as opposed to a drill etc. There are a couple of post on this site detailing this process.

I supplemented the double sided tape on my sensor mounts with a treatement all round with a hot glue gun. This is mainly to prevent water ingress, but may also help with retention.

5- Coding

Don't forget this part, especially if you are not certain your module came from an A2.

Using VCDS or VCDS lite, select module 76 (under Electronics 1 tab).

The instructions from Ross-Tech are here. http://wiki.ross-tech.com/wiki/index.php/Audi_A2_(8Z)_Parking_Aid

00102 is the code to use.

Mine was beeping, completely randomly until I coded it correctly.

This is a great project, but does need some research and decision making, and some 'flexibility' from the instructions depending on your situation and confidence.

It will take some time, just to sort the trim and connections, but is well worth it. Don't be afraid of the instrument cluster, but make sure you have taken instructions from somewhere beforehand.

There are plenty of associated posts here, and elsewhere (in German!), so it is worthwhile spending many hours researching advance.

Good luck!

Matt

Attachments

2work

Well Known Member

Evening Matt,I have just completed this task, so I offer some learnings and comments, rather than a specific 'How To'.

The instructions from @2work in the preceding post, along with other PDC threads, and the usual on-line videos etc provides plenty of info in relation to a full set of instructions, albeit only on the 'obvious' elements.

From my projects, below are a few pointers that, along with the other information, may make it easier for anyone wanting to attempt this valuable upgrade.

1- Hardware

2- Loom Install

3- Bumper removal and Sensor Loom

4- Sensor Install

5- Coding

1- Hardware

For this project, you will need

a controller module, likely from our club breakers, or ebay. I think any that start with 8Z... will likely do, as they are all pretty much the same and can be coded for A2. Look for Audi in the early 2000's, and that important item number. They start at £10!

A Loom from the module into the car, for power etc. This should have the correct 16 pin connector, which is the largest of the 3 into the module, likely green. It will have the 2 pin for the speaker also.

A loom to the sensors, from the module going into the rear bumper. This should have the correct 12 pin connector to the module.

A speaker (£7 new, on ebay).

...and of course, 4 sensors and corresponding mounts, again ebay.

Note, there are a few sizes, so you need to decide which sensors you wish to use, then get the correct mounts, and then make the correct size holes.

I used 23mm sensors, with the oblong centre, as I believe these are the same as factory fit. Round ones are fine, and smaller, as long as they are VAG compatible. Do some research, and check those measurements!

View attachment 113878

The looms are available from Kufatec direct, or from them via eBay (safer for possible Brexit issues....). Timmus may also be able to sell you them, but that may be old news....

It is important the sensor loom has a correct size grommet, to replace the one you will detach, to avoid any water going into the car. You could bodge the existing grommet, but that is not recommended. Any decent loom should have a grommet attached.

2- Loom install

The module should be installed in a very small cavity under the polystyrene block that holds the triangle/first aid kit.

Therefore, you will need to take off the left hand boot interior liner, and associated bits. There is quite a bit here, but have a look for various posts, manuals and videos on how to do this, and remember where all the bits go back!

Once you have taken off all the trim, you need to feed the loom up the lefthand side of the car, on the sill (follow the main loom already present), into the passenger footwell, then into the centre console, and up behind the pedals, to get to the instrument cluster.

My loom was not actually long enough except for the 3 wires which need to connect to the instruments, however I always intended to use alternative connections for the remaining wires.

The 3 I used to get to the instruments are,

CAN high

CAN low

K-line (diagnostics)

(also in this group is Gala (speed) which is not necessary, and can be taped to safety anywhere).

The remainder I changed to,

Earth - Passenger A pillar. There is a good point in there.

Constant 12v - A sub-fusebox in the passenger footwell, or any other constant permanent 12v supply you wish.

Ignition 12v - I managed to find another Black/Blue supply in the passenger A pillar, so just connected to that.

Reverse light - This is short, and can only be connected to the + for the reverse light on the left. I think it is Pin 1 on the connector to the bulb rack (Red/ Blue stripe?)

Have a look at this site and translation, which I found very useful. Not sure about the accuracy of the first column, but the notes especially are useful.

Einparkhilfe – A2-Freun.de Wiki

wiki.a2-freun.de

View attachment 113879

My loom came with no colours (all wires are white), but the last few inches of each have the name of the wire, and usefully, the pin number etc, so for example, the k-line wire had 'Diagnostics T32/28' or suchlike, so I could connect it easily.

This is very useful for me, as I am colourblind, and often have no idea of what colour wires are......or connectors, or even cars!

You may need to do a bit of homework here, and make changes as it suits your tools, capability and preferences. Some may not wish to open the instrument cluster, and connect to the CCU. I certainly had no desire to open the fusebox.......

For wires which need spliced into another cable, I used these. Cheap on ebay, and a lot easier than soldering etc, but perhaps not the best long term. You just need to do what you wish.

View attachment 113880

In my car, I have no Pin 6 on my OBD connector (2001, pre CANBUS for radio), so took the k-line to the instrument cluster.

There is quite a bit of work laying the loom, connecting it all up and ensuring the module and speaker etc are all mounted correctly. The module needs to have the connectors on the bottom of the module, with all cables tucked away, or the poly block will not fit back in correctly. See photo.

View attachment 113881

3- Bumper removal and sensor loom

This was the most difficult part for me. Follow the instructions (elsewhere) for bumper removal, but the bits I could have done knowing about are,

There are 2 screws you need to access after part-detaching the inner liner of the rear wheels. These are the most 'sunken' and difficult to see and access, of the many screws you will see. Just these 2 need to be taken out (not just loosened). See photo with yellow arrows (same on each side).

Then, you need to pull the side flap of the bumper out away from the car, so it comes out of the slot and clips, as shown in the photo. You may need to lever it out gently, without scratches!

Note the 2 screw positions. This shows why you have the remove the screws, to allow the holed tabs in the bumper to come out of the slots.

I had 3 tabs on my bumper, but only 2 screws through the slot. You may have 3.....

The rest of the bumper is as per other instructions - easy really.

You will then see the grommet on the lower left, for the loom to go through.

Lay that loom as it appears obvious. I tied mine with loose cable ties just to keep it all tidy.

4- Sensor Install.

Once you have carefully selected your sensors and mounts, you need to put the appropriate holes in your bumper.

I used a sheet metal punch, which created a perfectly sized hole and an excellent finish. I can only recommend this type of hole, as opposed to a drill etc. There are a couple of post on this site detailing this process.

I supplemented the double sided tape on my sensor mounts with a treatement all round with a hot glue gun. This is mainly to prevent water ingress, but may also help with retention.

5- Coding

Don't forget this part, especially if you are not certain your module came from an A2.

Using VCDS or VCDS lite, select module 76 (under Electronics 1 tab).

The instructions from Ross-Tech are here. http://wiki.ross-tech.com/wiki/index.php/Audi_A2_(8Z)_Parking_Aid

00102 is the code to use.

Mine was beeping, completely randomly until I coded it correctly.

This is a great project, but does need some research and decision making, and some 'flexibility' from the instructions depending on your situation and confidence.

It will take some time, just to sort the trim and connections, but is well worth it. Don't be afraid of the instrument cluster, but make sure you have taken instructions from somewhere beforehand.

There are plenty of associated posts here, and elsewhere (in German!), so it is worthwhile spending many hours researching advance.

Good luck!

Matt

Very good write up Sir, it will serve members well for many years. When doing this particular retrofit I solder into alternative points for the same feed but this is just personal preference.

Thank you so much for taking the time to share, extremely good of you. Also very glad to see the 23mm hole punch see more action than just the 2 rear bumpers from the current fleet on my driveway. More than happy for anyone else to borrow it for this purpose in the future.

Thanks again for sharing.

Kind regards,

Tom

Last edited:

Jellybean

A2OC Donor

Excellent write up, this needs to be filed, for future reference.I have just completed this task, so I offer some learnings and comments, rather than a specific 'How To'.

The instructions from @2work in the preceding post, along with other PDC threads, and the usual on-line videos etc provides plenty of info in relation to a full set of instructions, albeit only on the 'obvious' elements.

From my projects, below are a few pointers that, along with the other information, may make it easier for anyone wanting to attempt this valuable upgrade.

1- Hardware

2- Loom Install

3- Bumper removal and Sensor Loom

4- Sensor Install

5- Coding

1- Hardware

For this project, you will need

a controller module, likely from our club breakers, or ebay. I think any that start with 8Z... will likely do, as they are all pretty much the same and can be coded for A2. Look for Audi in the early 2000's, and that important item number. They start at £10!

A Loom from the module into the car, for power etc. This should have the correct 16 pin connector, which is the largest of the 3 into the module, likely green. It will have the 2 pin for the speaker also.

A loom to the sensors, from the module going into the rear bumper. This should have the correct 12 pin connector to the module.

A speaker (£7 new, on ebay).

...and of course, 4 sensors and corresponding mounts, again ebay.

Note, there are a few sizes, so you need to decide which sensors you wish to use, then get the correct mounts, and then make the correct size holes.

I used 23mm sensors, with the oblong centre, as I believe these are the same as factory fit. Round ones are fine, and smaller, as long as they are VAG compatible. Do some research, and check those measurements!

View attachment 113878

The looms are available from Kufatec direct, or from them via eBay (safer for possible Brexit issues....). Timmus may also be able to sell you them, but that may be old news....

It is important the sensor loom has a correct size grommet, to replace the one you will detach, to avoid any water going into the car. You could bodge the existing grommet, but that is not recommended. Any decent loom should have a grommet attached.

2- Loom install

The module should be installed in a very small cavity under the polystyrene block that holds the triangle/first aid kit.

Therefore, you will need to take off the left hand boot interior liner, and associated bits. There is quite a bit here, but have a look for various posts, manuals and videos on how to do this, and remember where all the bits go back!

Once you have taken off all the trim, you need to feed the loom up the lefthand side of the car, on the sill (follow the main loom already present), into the passenger footwell, then into the centre console, and up behind the pedals, to get to the instrument cluster.

My loom was not actually long enough except for the 3 wires which need to connect to the instruments, however I always intended to use alternative connections for the remaining wires.

The 3 I used to get to the instruments are,

CAN high

CAN low

K-line (diagnostics)

(also in this group is Gala (speed) which is not necessary, and can be taped to safety anywhere).

The remainder I changed to,

Earth - Passenger A pillar. There is a good point in there.

Constant 12v - A sub-fusebox in the passenger footwell, or any other constant permanent 12v supply you wish.

Ignition 12v - I managed to find another Black/Blue supply in the passenger A pillar, so just connected to that.

Reverse light - This is short, and can only be connected to the + for the reverse light on the left. I think it is Pin 1 on the connector to the bulb rack (Red/ Blue stripe?)

Have a look at this site and translation, which I found very useful. Not sure about the accuracy of the first column, but the notes especially are useful.

Einparkhilfe – A2-Freun.de Wiki

wiki.a2-freun.de

View attachment 113879

My loom came with no colours (all wires are white), but the last few inches of each have the name of the wire, and usefully, the pin number etc, so for example, the k-line wire had 'Diagnostics T32/28' or suchlike, so I could connect it easily.

This is very useful for me, as I am colourblind, and often have no idea of what colour wires are......or connectors, or even cars!

You may need to do a bit of homework here, and make changes as it suits your tools, capability and preferences. Some may not wish to open the instrument cluster, and connect to the CCU. I certainly had no desire to open the fusebox.......

For wires which need spliced into another cable, I used these. Cheap on ebay, and a lot easier than soldering etc, but perhaps not the best long term. You just need to do what you wish.

View attachment 113880

In my car, I have no Pin 6 on my OBD connector (2001, pre CANBUS for radio), so took the k-line to the instrument cluster.

There is quite a bit of work laying the loom, connecting it all up and ensuring the module and speaker etc are all mounted correctly. The module needs to have the connectors on the bottom of the module, with all cables tucked away, or the poly block will not fit back in correctly. See photo.

View attachment 113881

3- Bumper removal and sensor loom

This was the most difficult part for me. Follow the instructions (elsewhere) for bumper removal, but the bits I could have done knowing about are,

There are 2 screws you need to access after part-detaching the inner liner of the rear wheels. These are the most 'sunken' and difficult to see and access, of the many screws you will see. Just these 2 need to be taken out (not just loosened). See photo with yellow arrows (same on each side).

Then, you need to pull the side flap of the bumper out away from the car, so it comes out of the slot and clips, as shown in the photo. You may need to lever it out gently, without scratches!

Note the 2 screw positions. This shows why you have the remove the screws, to allow the holed tabs in the bumper to come out of the slots.

I had 3 tabs on my bumper, but only 2 screws through the slot. You may have 3.....

The rest of the bumper is as per other instructions - easy really.

You will then see the grommet on the lower left, for the loom to go through.

Lay that loom as it appears obvious. I tied mine with loose cable ties just to keep it all tidy.

4- Sensor Install.

Once you have carefully selected your sensors and mounts, you need to put the appropriate holes in your bumper.

I used a sheet metal punch, which created a perfectly sized hole and an excellent finish. I can only recommend this type of hole, as opposed to a drill etc. There are a couple of post on this site detailing this process.

I supplemented the double sided tape on my sensor mounts with a treatement all round with a hot glue gun. This is mainly to prevent water ingress, but may also help with retention.

5- Coding

Don't forget this part, especially if you are not certain your module came from an A2.

Using VCDS or VCDS lite, select module 76 (under Electronics 1 tab).

The instructions from Ross-Tech are here. http://wiki.ross-tech.com/wiki/index.php/Audi_A2_(8Z)_Parking_Aid

00102 is the code to use.

Mine was beeping, completely randomly until I coded it correctly.

This is a great project, but does need some research and decision making, and some 'flexibility' from the instructions depending on your situation and confidence.

It will take some time, just to sort the trim and connections, but is well worth it. Don't be afraid of the instrument cluster, but make sure you have taken instructions from somewhere beforehand.

There are plenty of associated posts here, and elsewhere (in German!), so it is worthwhile spending many hours researching advance.

Good luck!

Matt

Sent from my SM-N960F using Tapatalk