D

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PlasticMac

Member

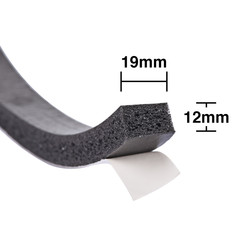

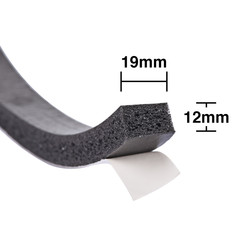

Buy a roll of self adhesive foam tape from Tool Station. Don't use aerosol foam, it'll just make a mess, and push the scuttle out of shape. It's virtually https://www.toolstation.com/stormguard-jumbo-rubber-foam-weatherstrip/p95977 impossible to clean up too.I purchased some expanding building trade window foam because my car is missing that length of foam located under the scuttle.

Could someone possibly send a picture of the location where Audi placed the foam beneath the scuttle?

View attachment 121694

View attachment 121695

Thanks

I used the Tool Station on mine, and it's perfect.

Stormguard Jumbo Rubber Foam Weatherstrip

Seal gaps around doors and windows effectively with this jumbo foam weatherstrip from Stormguard. The strip offers superior shock absorption to help protect your doors, windows, frames and surfaces, along with minimum compression, so it will keep on doing its job for many openings and closings...

Indi

Member

That looks like similar to what he’s using judging by the pictureBuy a roll of self adhesive foam tape from Tool Station. Don't use aerosol foam, it'll just make a mess, and push the scuttle out of shape. It's virtually https://www.toolstation.com/stormguard-jumbo-rubber-foam-weatherstrip/p95977 impossible to clean up too.

I used the Tool Station on mine, and it's perfect.

Mac.

Stormguard Jumbo Rubber Foam Weatherstrip

Seal gaps around doors and windows effectively with this jumbo foam weatherstrip from Stormguard. The strip offers superior shock absorption to help protect your doors, windows, frames and surfaces, along with minimum compression, so it will keep on doing its job for many openings and closings...www.toolstation.com

PlasticMac

Member

Sounded like that gap filling foam in a can to me.That looks like similar to what he’s using judging by the picture

But, looking at the pic, you're right, it is tape, but expands by itself after fitting. I think that'll lift the scuttle, the forward edge would pull out of the rubber moulding. Hope I'm wrong. The Tool Station stuff is almost exactly the same as the original, just a couple of mms wider.

Mac.

Last edited:

PlasticMac

Member

Just watched the video on the xpanda website. It's intended for sealing between two rigid surfaces, such as window frame and brickwork, expands to fill the gap.

It's described as an alternative to the aerosol foam. Not ideal for under the scuttle imo.

Mac.

It's described as an alternative to the aerosol foam. Not ideal for under the scuttle imo.

Mac.

D

Deleted member 20348

Guest

PlasticMac

Member

And the scuttle will come off easily, the foam tape doesn't stick to the underside of the scuttle?Hello,

Used it in the past on the tdi was alright. Thank you for looking out for my best interest.

Cheers for all the help and the pictures much appreciated all of you

It's the 15mm width roll.

View attachment 121712

Mac.

audifan

A2OC Donor

The foam is attached to the metal panel and not the plastic one. Suggest you try to follow the "step profile" of the plastic panel but make sure the plastic panel can still fit correctly and is not pushed up.. You may also want to consider blanking off some of the extra holes in the metal panel and divert the water to a single drain point well away from the gearbox.. Also ideal time to replace a worn wiper spindle grommet to prevent more water pouring onto the wiper motor.

D

Deleted member 20348

Guest

Hi MacAnd the scuttle will come off easily, the foam tape doesn't stick to the underside of the scuttle?

Mac.

The adhesive is applied to one side of the roll.

I'll take some pictures tomorrow before replacing the scuttle.

PlasticMac

Member

Yes, I know, I fitted the ToilStThe foam is attached to the metal panel and not the plastic one. Suggest you try to follow the "step profile" of the plastic panel but make sure the plastic panel can still fit correctly and is not pushed up.. You may also want to consider blanking off some of the extra holes in the metal panel and divert the water to a single drain point well away from the gearbox.. Also ideal time to replace a worn wiper spindle grommet to prevent more water pouring onto the wiper motor.

Cheers, so only sticky one side, that's what I was worried about. Wondered if it bonded with both sides, as it expanded, but no.Hi Mac

The adhesive is applied to one side of the roll.

I'll take some pictures tomorrow before replacing the scuttle.

Mac.

D

Deleted member 20348

Guest

The area underneath the windscreen had a full length strip of foam underneath it that was holding water. I can only guess that it was installed to stop the rubber/plastic part running along the bottom edge of the screen from sagging when fitting the plastic scuttle weather strip.

The old foam from under there was scraped out using trim tools. The old adhesive was softened with brake cleaner and removed using a piece of cloth put over the end of the trim tool.

Car polish was used to detail the area and the new roll of foam fitted.

Thanks to @Indi for the photograph of the foam contour which I studied for some time before coming to a conclusion.

I did not want to follow the Audi contour and chose to make a similar design that had the main aim of channeling water away from some areas.

I hope it functions in practice as per the design theory.

Aim: To drain water from the under the plastic scuttle to an area where it can be deposited and cause the least damage over time.

I would welcome any feed back on what you can see in the photos and flaws in the design.

I have a lot of tape left over.

@PlasticMac the Storm guard tape you have suggested looks like a better product than the one I chose. I will try that manufacturer in the future.

Thank you to all who contributed to this mini-project

Note:

The foam I bought takes 5 minutes to expand. The image was taken immediately after fitting. The foam had not yet expanded.

Last edited by a moderator:

Indi

Member

I suspect originally water wasn’t supposed to get under the skuttle panel at all, but nowadays is on most A2s as the clip/press fitting/seal along the top edge isn’t so secure after 20 yearsView attachment 121890

The area underneath the windscreen had a full length strip of foam underneath it that was holding water. I can only guess that it was installed to stop the rubber/plastic part running along the bottom edge of the screen from sagging when fitting the plastic scuttle weather strip.

The old foam from under there was scraped out using trim tools. The old adhesive was softened with brake cleaner and removed using a piece of cloth put over the end of the trim tool.

Car polish was used to detail the area and the new roll of foam fitted.

Thanks to @Indi for the photograph of the foam contour which I studied for some time before coming to a conclusion.

I did not want to follow the Audi contour and chose to make a similar design that had the main aim of channeling water away from some areas.

I hope it functions in practice as per the design theory.

Aim: To drain water from the under the plastic scuttle to an area where it can be deposited and cause the least damage over time.

I would welcome any feed back on what you can see in the photos and flaws in the design.

I have a lot of tape left over.

@PlasticMac the Storm guard tape you have suggested looks like a better product than the one I chose. I will try that manufacturer in the future.

View attachment 121891

Thank you to all who contributed to this mini-project

D

Deleted member 20348

Guest

Taking your idea into consideration @Indi I have a question.

.. Would the foam have been fitted to reduce vibrations? A sound insulation barrier to reduce noise being transferred to the cabin?

.. Why did Audi choose such an odd path when sticking the tape in that area, those contours are specific.

Maybe it's like what was mentioned earlier, the foam is like that because when the scuttle plastic part is fitted the foam takes up the seating position and the fitment is snug?

I don't expect you to have all the answers. These are thoughts that were in my head when I was designing the new contour.

.. Would the foam have been fitted to reduce vibrations? A sound insulation barrier to reduce noise being transferred to the cabin?

.. Why did Audi choose such an odd path when sticking the tape in that area, those contours are specific.

Maybe it's like what was mentioned earlier, the foam is like that because when the scuttle plastic part is fitted the foam takes up the seating position and the fitment is snug?

I don't expect you to have all the answers. These are thoughts that were in my head when I was designing the new contour.

PlasticMac

Member

Spread a little silicone grease into the clip/press fitting before engaging the scuttle. Helps the fit, and keeps water out.I suspect originally water wasn’t supposed to get under the skuttle panel at all, but nowadays is on most A2s as the clip/press fitting/seal along the top edge isn’t so secure after 20 years

I'd say the foam is to stop the scuttle rattling and keep it fairly rigid.

Mac.

D

Deleted member 20348

Guest

Hi @PlasticMac ,

I have some of the silicone grease in the shed. I did a similar thing to what you suggest.

I cleaned the plastic clip with autoglym rubber and plastic polish.

Over the years the grit from the windscreen is deposited in the clip fixing channel this makes the plastic scuttle problematic when you want to remove it. Up to three trim removal tools were used at the same time to prop open and slowly lift small sections at a time to get the scuttle trim to release .

I have some of the silicone grease in the shed. I did a similar thing to what you suggest.

I cleaned the plastic clip with autoglym rubber and plastic polish.

Over the years the grit from the windscreen is deposited in the clip fixing channel this makes the plastic scuttle problematic when you want to remove it. Up to three trim removal tools were used at the same time to prop open and slowly lift small sections at a time to get the scuttle trim to release .

Last edited by a moderator:

Little Dog

A2OC Donor

I thought the foam was there to direct any water to drains. If it stopped vibration only a couple of lumps of it would do the job.

I looked at the holes in the scuttle (metal side of scuttle), looked at where they would drain to. One was all over the vacuum and turbo waste gate switches so that got taped over. Then I positioned my foam strips to direct water to one central drain.

What I have is very similar to the factory foam route.

I looked at the holes in the scuttle (metal side of scuttle), looked at where they would drain to. One was all over the vacuum and turbo waste gate switches so that got taped over. Then I positioned my foam strips to direct water to one central drain.

What I have is very similar to the factory foam route.

PlasticMac

Member

I followed the original route very carefully.I thought the foam was there to direct any water to drains. If it stopped vibration only a couple of lumps of it would do the job.

I looked at the holes in the scuttle (metal side of scuttle), looked at where they would drain to. One was all over the vacuum and turbo waste gate switches so that got taped over. Then I positioned my foam strips to direct water to one central drain.

What I have is very similar to the factory foam route.

I had a small bit missing from one end of the original scuttle, and replaced it with one from @Ami It was not too bad under there. But in places, where the foam strip is very compressed, (scuttle close to metal), the original foam was much degraded. I first tried quite a dense, closed cell foam, but it would not compress enough to get the scuttle to fit correctly. The foam I used replicates the original, in density and height, but is a couple of mm wider. I did shape the width around the wiper, and washer jets.

You do need to throughly clean the grooves in the screen trim, quite a job to get it absolutely clear of twenty years of accumulated debris. Unless you do, the join between scuttle and screen trim will not seal.

Mac.

D

Deleted member 20348

Guest

Hi,

@Little Dog & @PlasticMac did you take photographs once you had replaced the foam?

They would be useful to others. No offense intended @Indi your foam is a beautiful example of what most people's car foam will look like after 20 years.

I would like to make a comparison of the contour pathway taken across the scuttle by anyone who has a photo.

@Little Dog brings up a good point in his reply.

Petrol and diesel engine cars have different component parts below where I have channeled the water.

The diesel would have the turbo at one side and the vacuum electronics at the other.

The petrol has sensor electrical connectors at one side and gear cables at the other side.

The FSI and TDi90.

I am not familiar with the set up under the bonnet.

@Little Dog & @PlasticMac did you take photographs once you had replaced the foam?

They would be useful to others. No offense intended @Indi your foam is a beautiful example of what most people's car foam will look like after 20 years.

I would like to make a comparison of the contour pathway taken across the scuttle by anyone who has a photo.

@Little Dog brings up a good point in his reply.

Petrol and diesel engine cars have different component parts below where I have channeled the water.

The diesel would have the turbo at one side and the vacuum electronics at the other.

The petrol has sensor electrical connectors at one side and gear cables at the other side.

The FSI and TDi90.

I am not familiar with the set up under the bonnet.

Last edited by a moderator: