Little Dog

A2OC Donor

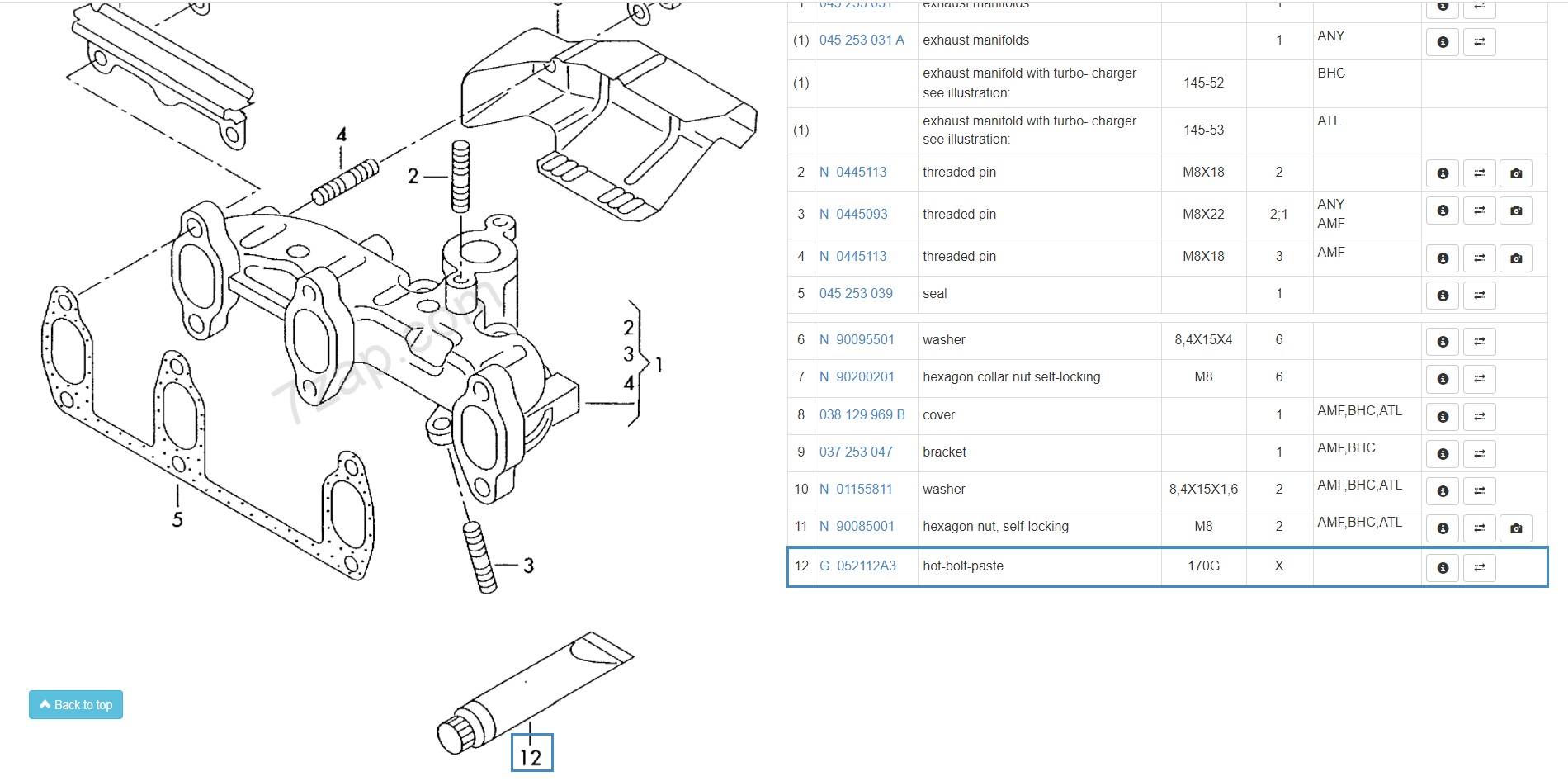

I'm in 7 Zap looking for part numbers for gaskets and seals for a repair that I have ongoing. I opened the wrong parts list and spotted item 12 hot bolt paste:

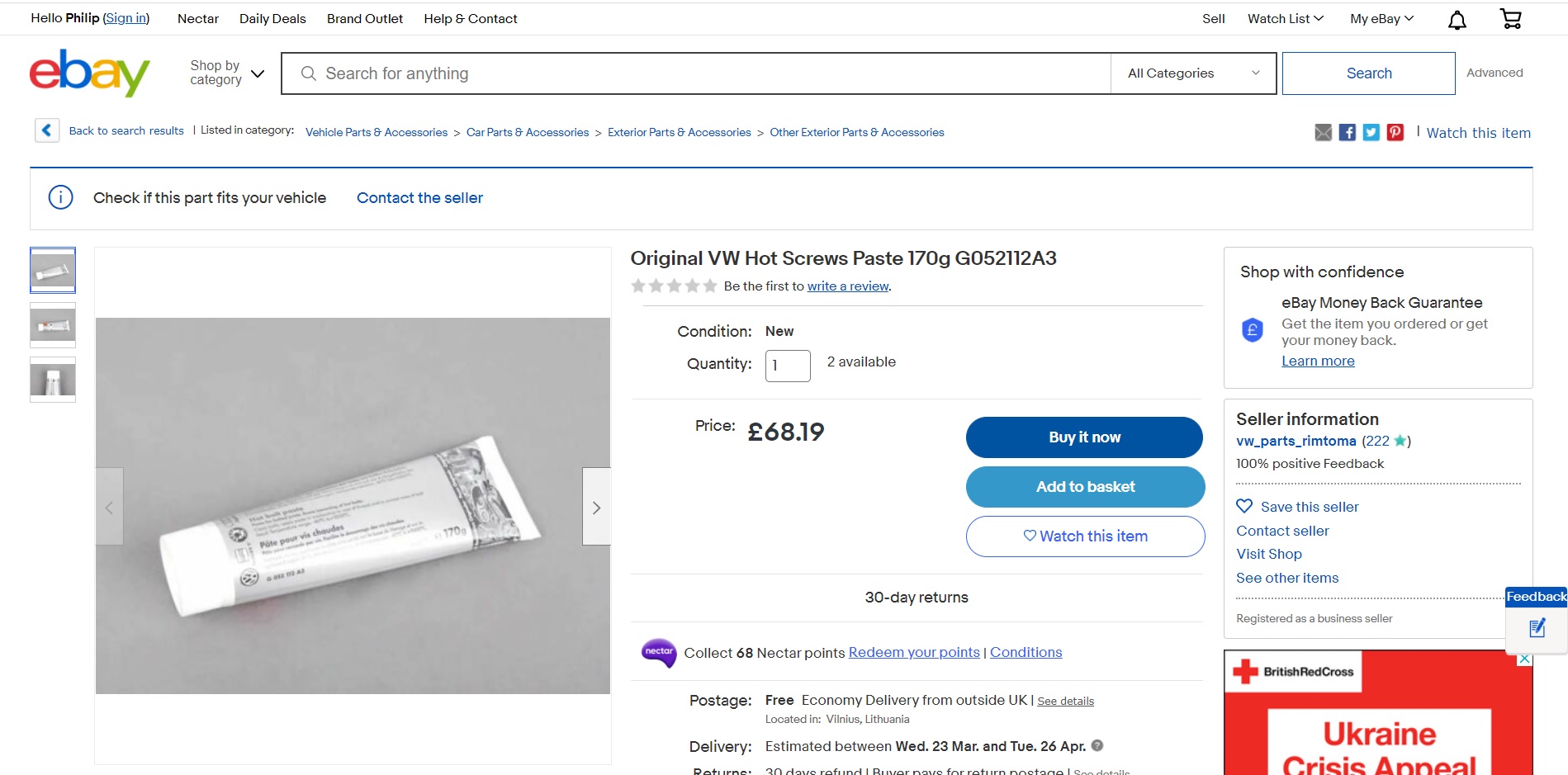

I thought I'll have some of that; got exhaust related jobs on other cars to get done. Errr, no I won't:

Does any body know what this stuff is? I already have a tub of Febi very high temperature grease that I use on glow plugs.

I thought I'll have some of that; got exhaust related jobs on other cars to get done. Errr, no I won't:

Does any body know what this stuff is? I already have a tub of Febi very high temperature grease that I use on glow plugs.