D

Deleted member 20348

Guest

Hi All,

Recently I removed a few body panel and both doors. It took some time getting the alignment right but it's worth the extra effort.

Refitting the sill and trim pieces is tedious.

If your fitting new rear brake lines remove the lower row of sill screws and heat it and bend to get access. Hope that works

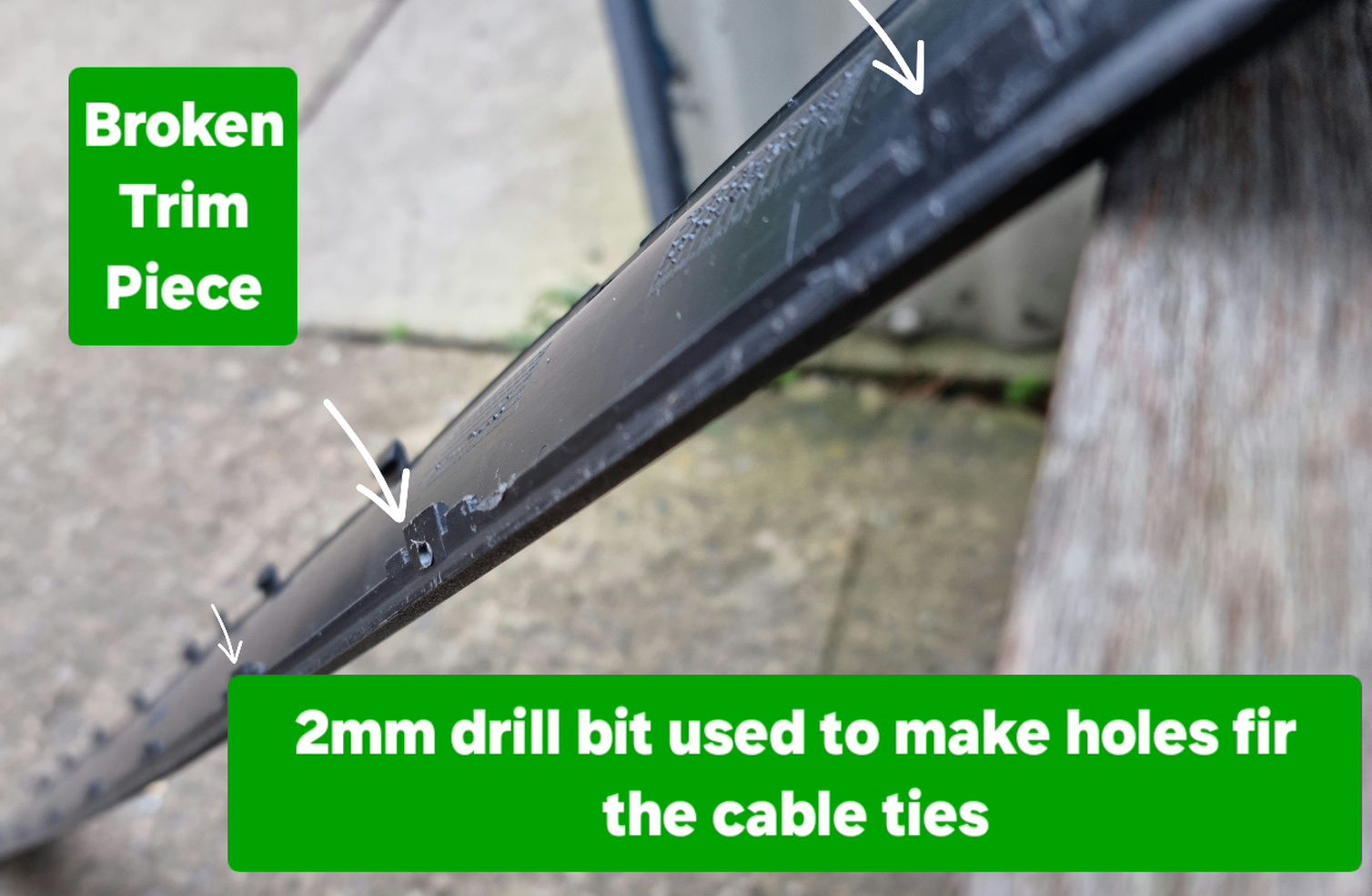

I snapped all the lower clips on the drivers side longer trim piece.

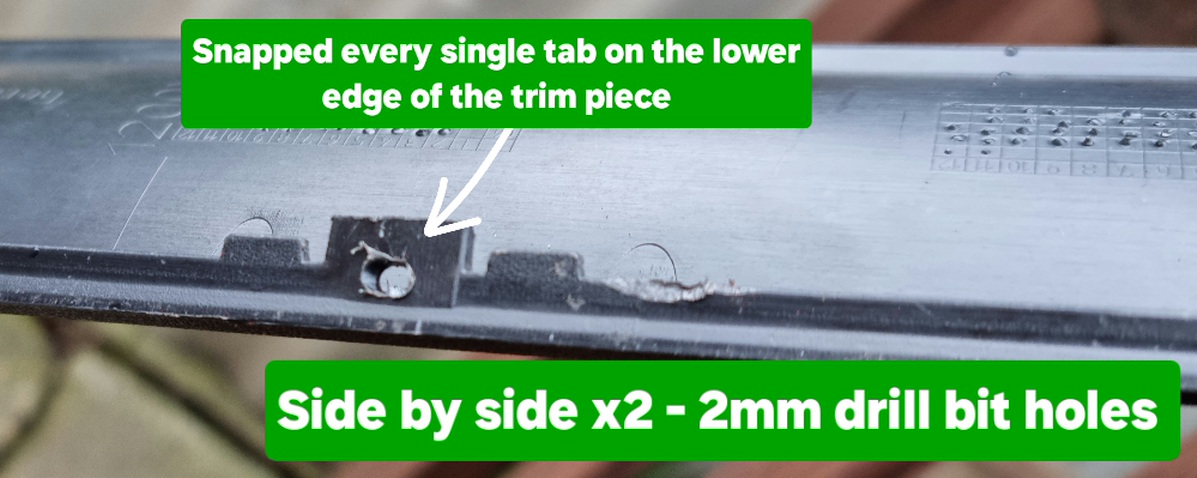

After puzzling for a while I came up with a plan to drill 2 side by side 2mm holes and remove the piece inbetween with the the drill bit to erode away at it.

The image is the lower tab minus the triangular end piece that was once the trim mount clip. I won't spend money on new plastic parts the worlds already got enough of that laying about.

I came up with a rescue plan that was acceptable but slightly destructive. Out came the cable ties and Lidl drill.

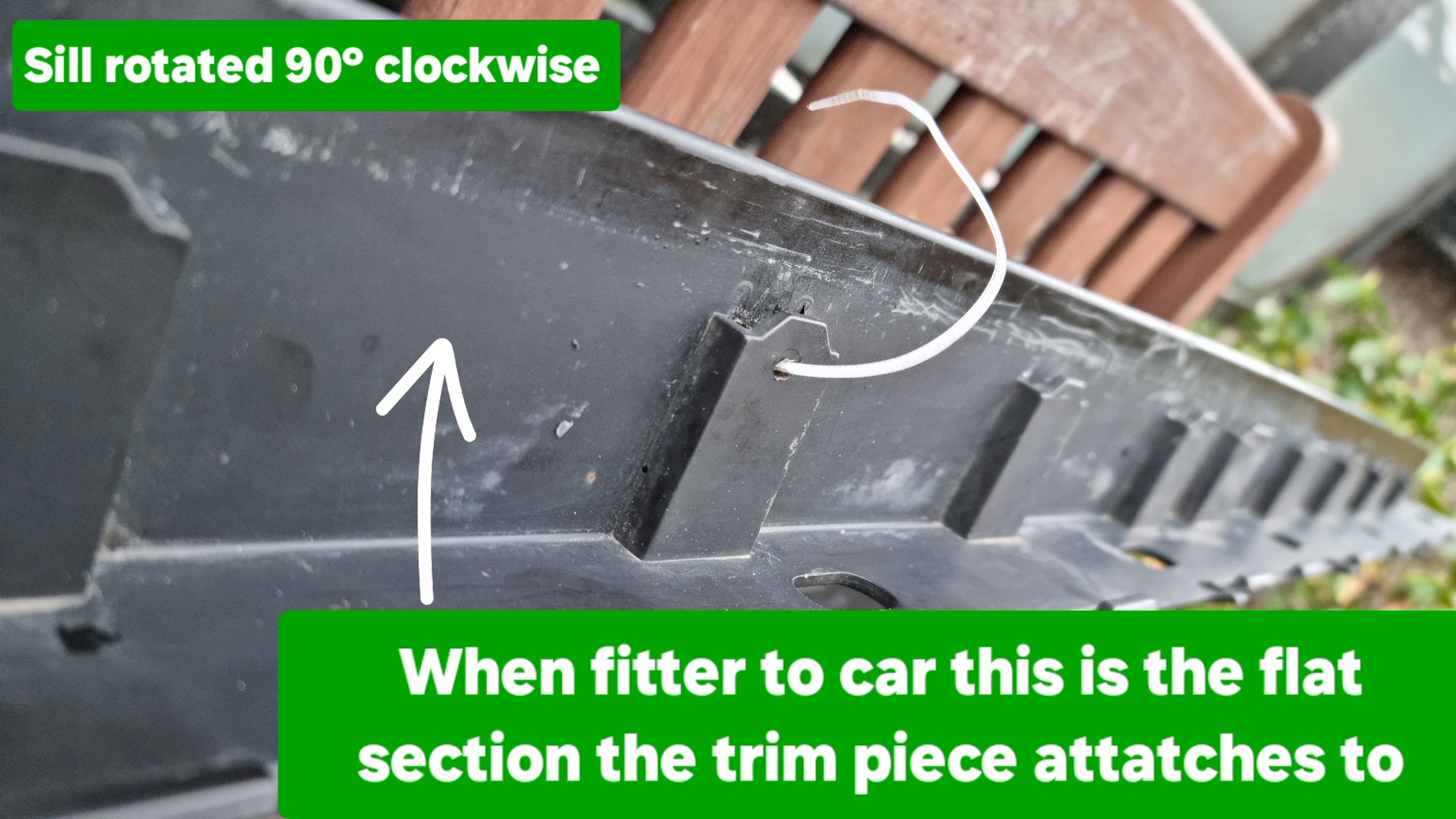

First off some cable tie sized holes in the raised sections of the sill near to where the trim attatches. The small cable ties were pushed up through from inside the sill.

A hole was made in the trim and the two halves test fitted off the car to see if the plan would work.

The sill was mounted on the car with two of the top body mounting screws done up half way. The cable ties were pushed through the trim and looped back and done up under the sill.

If you have needle nose piers you may need them to join the cable tie together.

Did I mention don't take the sills off the car unless you fancy buying a full set of plastic trim parts from Audi Tradition.

These are definite candidate for the 3D printer but probably too long to make.

Good Luck!

Edit

Just a quick note to say the above is is not a set of instructions and I'm no mechanic.

Recently I removed a few body panel and both doors. It took some time getting the alignment right but it's worth the extra effort.

-The Sill and Trim-

Refitting the sill and trim pieces is tedious.

If your fitting new rear brake lines remove the lower row of sill screws and heat it and bend to get access. Hope that works

I snapped all the lower clips on the drivers side longer trim piece.

After puzzling for a while I came up with a plan to drill 2 side by side 2mm holes and remove the piece inbetween with the the drill bit to erode away at it.

The image is the lower tab minus the triangular end piece that was once the trim mount clip. I won't spend money on new plastic parts the worlds already got enough of that laying about.

I came up with a rescue plan that was acceptable but slightly destructive. Out came the cable ties and Lidl drill.

First off some cable tie sized holes in the raised sections of the sill near to where the trim attatches. The small cable ties were pushed up through from inside the sill.

A hole was made in the trim and the two halves test fitted off the car to see if the plan would work.

The sill was mounted on the car with two of the top body mounting screws done up half way. The cable ties were pushed through the trim and looped back and done up under the sill.

If you have needle nose piers you may need them to join the cable tie together.

Did I mention don't take the sills off the car unless you fancy buying a full set of plastic trim parts from Audi Tradition.

These are definite candidate for the 3D printer but probably too long to make.

Good Luck!

Edit

Just a quick note to say the above is is not a set of instructions and I'm no mechanic.

Last edited by a moderator:

![20240317_155418-COLLAGE[1].jpg 20240317_155418-COLLAGE[1].jpg](https://a2oc.ams3.digitaloceanspaces.com/data/attachments/106/106661-d6007b8fa54abe5689845c9b966475f9.jpg)

![20240322_211903-COLLAGE[1].jpg 20240322_211903-COLLAGE[1].jpg](https://a2oc.ams3.digitaloceanspaces.com/data/attachments/106/106662-c0df869f726e2ba5d7b7da5f780bdb10.jpg)

![20240317_154639-COLLAGE[1].jpg 20240317_154639-COLLAGE[1].jpg](https://a2oc.ams3.digitaloceanspaces.com/data/attachments/106/106672-f6084c78ba6213cbfcc6bdd6b4744b69.jpg)

![20240318_144946[1].jpg 20240318_144946[1].jpg](https://a2oc.ams3.digitaloceanspaces.com/data/attachments/106/106667-976eaaf0b948bf8328a69fb47ebbd01c.jpg)