D

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

D

Deleted member 20348

Guest

Slightly miffed by this new product. Looks had it.

It will be going back

Joga

A2OC Donor

You bought it with the fan included? I might have missed if it is already covered, but which brand and art no is that?View attachment 119911

View attachment 119912

Slightly miffed by this new product. Looks had it.

View attachment 119914

It will be going back

D

Deleted member 20348

Guest

Indi

Member

This is, I would assume, a rotifer?Page 5

Who would have thought?

It's a comfy place to be.

The questions have dried up and there's just the odd 'like' thumbs now and again.

Here is a picture of a wheel animal to ponder.

View attachment 119875

Photographed by Charles Krebs

D

Deleted member 20348

Guest

One of nature's recyclers.

D

Deleted member 20348

Guest

Meanwhile whilst waiting on a replacement radiator the plastic sills were removed (26/02/24).

If you would like to read how I removed them you may follow this link.

www.a2oc.net

www.a2oc.net

The drivers side wing will be replaced but to gain access to the two fixings removal the sill is required.

Two sturdy looking fixings

If you would like to read how I removed them you may follow this link.

Sill Removal Replacement Plastic Clip Preservation

Have you been putting off removing those lower sill panels for a number of years? I'll attempt to demystify this job in the next couple of threads. Good luck! :) 👍

www.a2oc.net

www.a2oc.net

The drivers side wing will be replaced but to gain access to the two fixings removal the sill is required.

Two sturdy looking fixings

Last edited by a moderator:

DaveySprocket

A2OC Donor

Always a very rewarding moment, good work!Engine working

D

Deleted member 20348

Guest

Thank you. @DaveySprocket

The car started first time on old petrol, the top end is noisy but possibly not run long enough for oil to circulate?

I will keep on monitoring the cooling and lubrication for the first 100 miles or so.

The car started first time on old petrol, the top end is noisy but possibly not run long enough for oil to circulate?

I will keep on monitoring the cooling and lubrication for the first 100 miles or so.

Little Dog

A2OC Donor

If you ran the oil up to pressure then it has circulated. Tappets can rattle on a little while but in my experience not for long.

D

Deleted member 20348

Guest

Inspect for tarnish and residue

The best outcome would be they do calm down. As we know noise is energy being released as sound waves.

If there's noise there's probably friction so some heat and wear going on too. I intend to use this first batch of new oil for a short period as an engine flush.

I used a heavy weight 10w40 oil to hopefully catch more particles and hold them in suspension. It's a theory certainly not scientific

In my mind I imagine a short interval oil change to be a good investment. The vehicle may run for another 10 years and this may give it chance to get there?

I'm using the....

Precautionary Principal,... how to dodge Murphys law.

Last edited by a moderator:

D

Deleted member 20348

Guest

(28/02/24)

Discs and pad refresh

www.a2oc.net

Today's job is to service the brake fluid it's gone dark green and resembles used power steering fluid.

www.a2oc.net

Today's job is to service the brake fluid it's gone dark green and resembles used power steering fluid.

Discs and pad refresh

Bleeding the brakes via VCDS (ABS unit too)

Hi, A member contacted me directly the other day and asked if I could help. He was having trouble bleeding the brakes and could not get a firm pedal. He had lost his brakes when a calliper piston seal went and he lost all of the fluid. I had heard that if you run the brake fluid dry and air...

www.a2oc.net

www.a2oc.net

Last edited by a moderator:

Little Dog

A2OC Donor

I’ve never successfully fixed a noisy petrol engine head by replacing oil or hydraulic tappets. The ticking noise on both occasions was cased by combustion gasses escaping. One engine had damaged valve seats and the other a small hole in the exhaust manifold gasket.

Your engine looks like it has run a bit hot in the past.

Your engine looks like it has run a bit hot in the past.

D

Deleted member 20348

Guest

Yes, as suspected but unconfirmed until I removed that oil sensor.Friday 9th February 2024

Hello

At about 2030 hours I went to the shed to check the condition of a couple of parts taken from the 67k engine.

What I found was damage caused by an engine that has got hot. Hot enough to melt and deform plastic.

Speculation,...

Update 12/02/24

The Mot History Check for CV05 HVT reports that the cooling fan is inoperative

I mixed up the MOT history's, it was KA05JYS that had the inoperative fan.

In this situation it's a gamble on will it or won't it run and run on reliably?

I did see it running before purchasing and checked for the usual HGF signs. I drove the car off the trailer and onto the driveway, can't be all that bad?

On the bright side if a replacement engine is required, fitting will be much quicker as I won't be dismantling a parts car at the same time.

The crystal blue write off has provided many good parts and I fully recommend buying a parts car and saving as much of it as you can.

It's a great learning experience and your not worried about making mistakes when disassembling.

If you have the space, time, tools and gumption to do this.... Go for it.

Still on a Winner!

A twist of fate.....

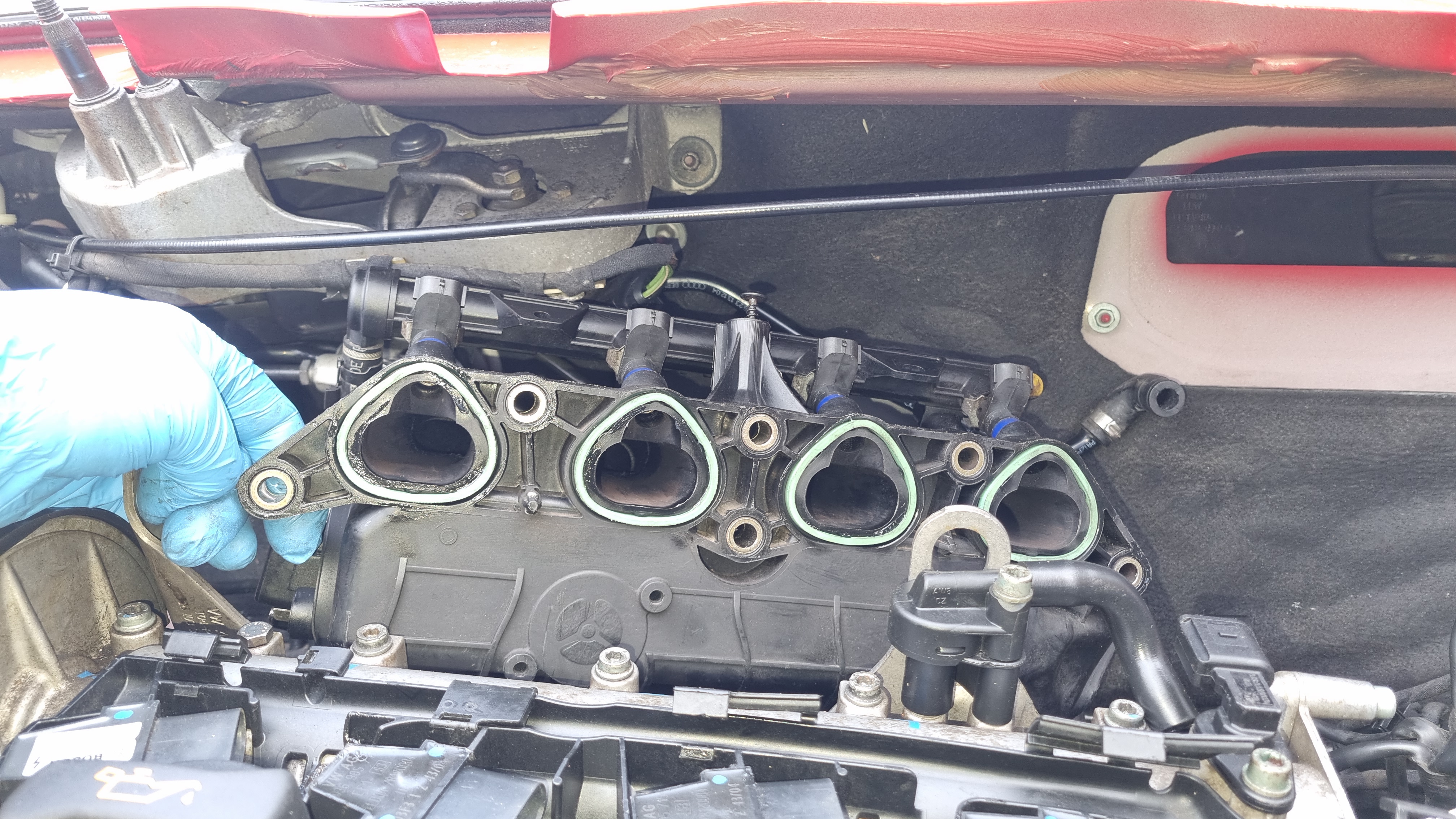

View attachment 119006

Crank case oil separator

View attachment 119007

Air intake manifold

HGF= head gasket failure

@Little Dog thank you for your input it's always good to have that second opinion. Plus you often spot stuff I've missed.

Your help is appreciated.

Last edited by a moderator:

Little Dog

A2OC Donor

I’d bore scope that engine, try and get some views of open valves. Also I’d try to get some views of internal plastic components. Does it have a sump baffle like a TDi?

D

Deleted member 20348

Guest

Last edited by a moderator:

D

Deleted member 20348

Guest

(29/02/24)

The radiator was fitted and the engine has done two heat cycles. The VCDS scan reported 17961 Barometric / Manifold Pressure Sensor

P1553 - 35- 10 Implsusable Correlation - Intermittent.

I'll need to log pressure from MAP in VCDS.

NOTE

I will be stating the obvious from here onwards, diagnostic work takes place like this for me. Warning! You may experience tedium with the following content.

From Latin plausibilis (“deserving applause, praiseworthy, acceptable, pleasing”), from the participle stem of plaudere (“to applaud”).

Were looking for the opposite of this which the best word I can find is 'unacceptable'.

Correlation usually refers to the degree to which a pair of variables are linearly relate.

Now I've got my head around what 'implausible correlation' means I'm looking to fix those 'unacceptable variables'.

The other fault code word 'intermittent' is a good clue. By this it means it happens some of the time but not others.

Therefore could we be looking for a device on the car or a driver input such as applying the brakes that has this kind of characteristic.

I wasn't using the brakes so it is unlikely to be the brake boost vac line.

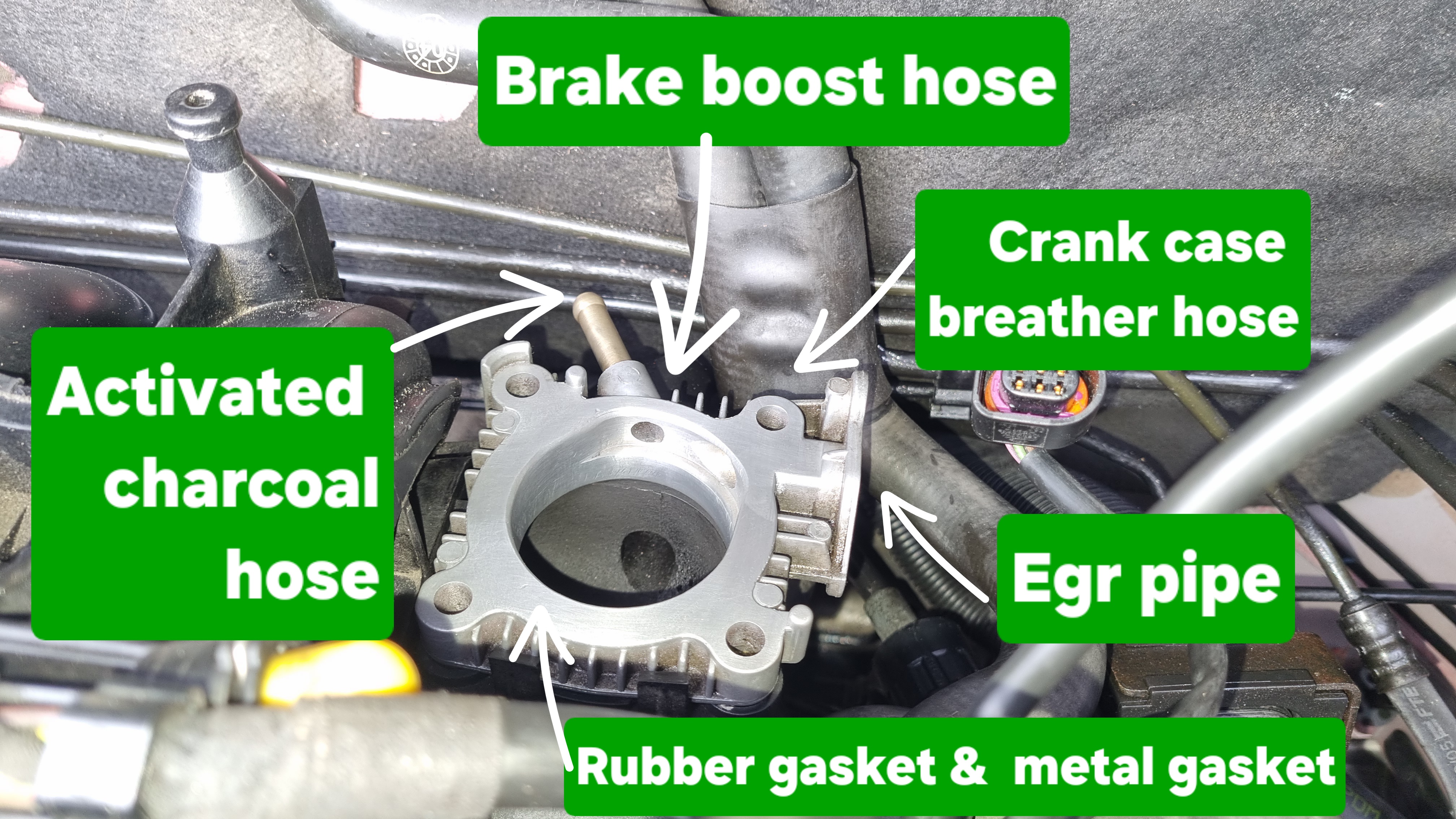

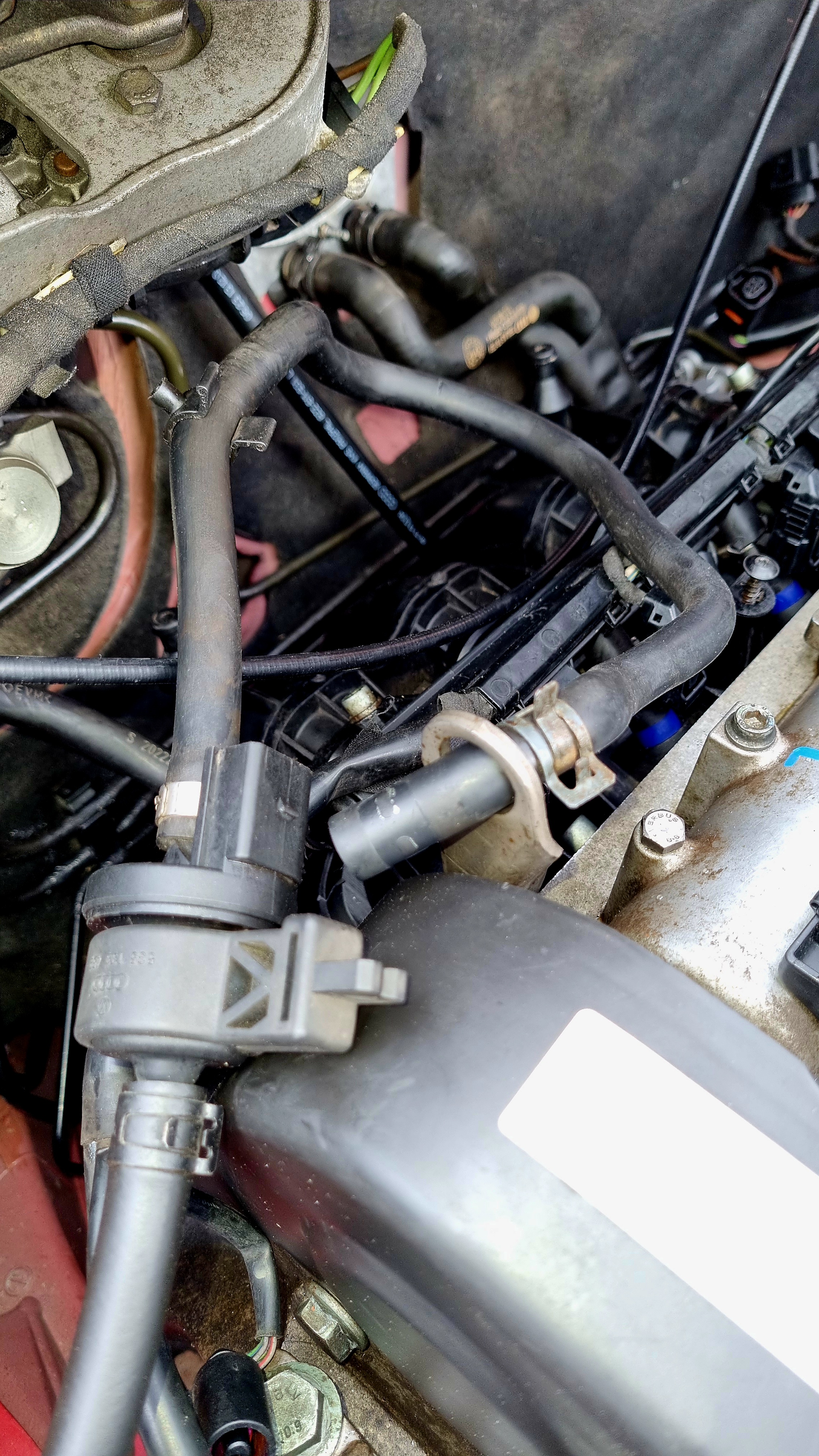

The other options would be the EGR or the active charcoal valve. I know that if the EGR is malfunctioning that the ECU can detect a fault but I'm unsure that the ECU doesn't have the ability to do this on the active charcoal valve so that's where I will begin.

The ECU monitors the manifold pressure sensor and compares the actual temperature & pressure data to the engine map (expected values). But there is a fault code reporting an error.

The throttle body meters the air entering the manifold and that volume of air

held in the intake manifold is contained by multiple seals that sit upon sealing surfaces plus the many joints and clamps on rubber hoses.

But what I'm getting at is there is the possibility for unmetered air to be added or lost.

Not forgetting the exhaust gas recirculation valve the three metal gasket seals and the integrity of the pipe that all enter the air intake after the ECU controlled throttle body butterfly flap.

In summary...

Brake boost hose

Crank case breather and hose

Activated charcoal valve

Manifold & throttle body seals

Manifold & throttle body seals

On the plus side the engine tapping noise has reduced.

Have a great day!

The radiator was fitted and the engine has done two heat cycles. The VCDS scan reported 17961 Barometric / Manifold Pressure Sensor

P1553 - 35- 10 Implsusable Correlation - Intermittent.

I'll need to log pressure from MAP in VCDS.

NOTE

I will be stating the obvious from here onwards, diagnostic work takes place like this for me. Warning! You may experience tedium with the following content.

From Latin plausibilis (“deserving applause, praiseworthy, acceptable, pleasing”), from the participle stem of plaudere (“to applaud”).

Were looking for the opposite of this which the best word I can find is 'unacceptable'.

Correlation usually refers to the degree to which a pair of variables are linearly relate.

Now I've got my head around what 'implausible correlation' means I'm looking to fix those 'unacceptable variables'.

The other fault code word 'intermittent' is a good clue. By this it means it happens some of the time but not others.

Therefore could we be looking for a device on the car or a driver input such as applying the brakes that has this kind of characteristic.

I wasn't using the brakes so it is unlikely to be the brake boost vac line.

The other options would be the EGR or the active charcoal valve. I know that if the EGR is malfunctioning that the ECU can detect a fault but I'm unsure that the ECU doesn't have the ability to do this on the active charcoal valve so that's where I will begin.

The ECU monitors the manifold pressure sensor and compares the actual temperature & pressure data to the engine map (expected values). But there is a fault code reporting an error.

The throttle body meters the air entering the manifold and that volume of air

held in the intake manifold is contained by multiple seals that sit upon sealing surfaces plus the many joints and clamps on rubber hoses.

But what I'm getting at is there is the possibility for unmetered air to be added or lost.

Not forgetting the exhaust gas recirculation valve the three metal gasket seals and the integrity of the pipe that all enter the air intake after the ECU controlled throttle body butterfly flap.

In summary...

Brake boost hose

Crank case breather and hose

Activated charcoal valve

On the plus side the engine tapping noise has reduced.

Last edited by a moderator:

Indi

Member

I’ll watch with interest, I won’t be looking at mine for a while longer I feel, got several more serious jobs to do before that gets to the top of the list…(29/02/24)

The radiator was fitted and the engine has done two heat cycles. The VCDS scan reported 17961 Barometric / Manifold Pressure Sensor

P1553 - 35- 10 Implsusable Correlation - Intermittent.

I'll need to log pressure from MAP in VCDS.

What is the giveaway in the pictures for the engine having ran hot in the past?I’ve never successfully fixed a noisy petrol engine head by replacing oil or hydraulic tappets. The ticking noise on both occasions was cased by combustion gasses escaping. One engine had damaged valve seats and the other a small hole in the exhaust manifold gasket.

Your engine looks like it has run a bit hot in the past.