You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Project EUD (2001 Jaipur Red TDI AMF)

- Thread starter 2work

- Start date

2work

Well Known Member

Evening all,

Not much to report on right now as been quite busy with all thing not involving A2s. I do still have the WhiteLine Rear ARB to fit which hopefully will happen on Sunday if the weather is being kind.

Whilst I say I’ve been busy with non-A2 related things, I have managed to spend a few hours connected with the 3DcolorMFD developers. They have been trying out some updated features and addressing some of the niggles that the current A2 firmware has. Such an amazing after sales support this project has. I’m quite sure that these screens will be utterly brilliant in the coming weeks. That said they’re already pretty darn good.

During the process of working with them they asked for a few pictures to add to their project pages:

Facebook

Instagram

YouTube

Hopefully I can come back to you all in the coming days/weeks to update you on the progress with this program.

Kind regards,

Tom

Not much to report on right now as been quite busy with all thing not involving A2s. I do still have the WhiteLine Rear ARB to fit which hopefully will happen on Sunday if the weather is being kind.

Whilst I say I’ve been busy with non-A2 related things, I have managed to spend a few hours connected with the 3DcolorMFD developers. They have been trying out some updated features and addressing some of the niggles that the current A2 firmware has. Such an amazing after sales support this project has. I’m quite sure that these screens will be utterly brilliant in the coming weeks. That said they’re already pretty darn good.

During the process of working with them they asked for a few pictures to add to their project pages:

YouTube

Hopefully I can come back to you all in the coming days/weeks to update you on the progress with this program.

Kind regards,

Tom

Last edited:

VonB

Member

Hi Tom,Evening Joakim,

I’ll go for a short drive in the next hour or 2 to see how it is at night. Think it’ll be fine though as it’s been in the other Audi’s in the past.

I do have the S3 cluster with the RPM scales that go up to 8k just like the FSI. I’ve also got the C5 Quattro KPH scales which go up to 260 kpm. Both scales are of course in white and wound be spot on for a FSI over in Europe.

Do you have a FSI Sir.

Kind regards,

Tom

I’d be interested in those 2 dials for my ‘Euro A2’ if you still have them kicking around?

PM me with a possible price?

Cheers,

Stuart

2work

Well Known Member

Evening Stuart,

I’ve just got back in from playing with my instrument clusters eeprom/dump file to correct the hex data values so the pointers read correctly with the white scales, finally sorted and perfect. This is a new area for me but worked out a few things along the way too.

I’m no expert on this subject yet but have a couple of sacrificial clusters to play with to tinker the values; it’s all a fun learning experience.

As for the white 8k rpm and 260kph scales. They are your Sir. I’ll send a PM shortly or in the morning. I’m sure the postage won’t be massively expensive but will check and let you know once I’ve got your full postal address (which we can sort over PM).

Kind regards,

Tom

I’ve just got back in from playing with my instrument clusters eeprom/dump file to correct the hex data values so the pointers read correctly with the white scales, finally sorted and perfect. This is a new area for me but worked out a few things along the way too.

I’m no expert on this subject yet but have a couple of sacrificial clusters to play with to tinker the values; it’s all a fun learning experience.

As for the white 8k rpm and 260kph scales. They are your Sir. I’ll send a PM shortly or in the morning. I’m sure the postage won’t be massively expensive but will check and let you know once I’ve got your full postal address (which we can sort over PM).

Kind regards,

Tom

2work

Well Known Member

Hello all,

I’m hoping today is the day when I can fit some recent purchases:

As you can see above there is the WhiteLine Rear ARB with its accessories.

Also above you’ll of course see a pair of Bilstein B4s with Bilstein bump stops and dust covers. These were actually required as the rear shocks and rubbers are fine but thought whilst I’m undoing bolts in that area I might as well go for a total refresh to match the recently fitted KYB rear spring.

The new strut tops haven’t arrived so contemplating just braising the currently fitted items and return the new items when they finally arrive.

I have a few other little tasks to complete this morning but hopefully I’ll have the new Jack out after lunch to remove the rear wheels and to tackle one of my least favourite tasks - wheel arch miner removal. I know it’s an easy job but for some reason I just don’t like doing them. I’d rather conduct a complete dashboard swap than remove 4 wheel arch liners!

Looking forward to the ride difference with the rear ARB installed. I’ll go the medium setting and adjust from there in time to suit my requirements.

Kind regards,

Tom

I’m hoping today is the day when I can fit some recent purchases:

As you can see above there is the WhiteLine Rear ARB with its accessories.

Also above you’ll of course see a pair of Bilstein B4s with Bilstein bump stops and dust covers. These were actually required as the rear shocks and rubbers are fine but thought whilst I’m undoing bolts in that area I might as well go for a total refresh to match the recently fitted KYB rear spring.

The new strut tops haven’t arrived so contemplating just braising the currently fitted items and return the new items when they finally arrive.

I have a few other little tasks to complete this morning but hopefully I’ll have the new Jack out after lunch to remove the rear wheels and to tackle one of my least favourite tasks - wheel arch miner removal. I know it’s an easy job but for some reason I just don’t like doing them. I’d rather conduct a complete dashboard swap than remove 4 wheel arch liners!

Looking forward to the ride difference with the rear ARB installed. I’ll go the medium setting and adjust from there in time to suit my requirements.

Kind regards,

Tom

2work

Well Known Member

Hello again,

These are the rear shocks that I’ve just removed:

Yes they have the 8Z0 part number stamped on so guessing the else are some 23 years old. The dust covers are also original too.

You’ve already seen the new shock earlier but here they are fitted:

Quite dirty in and around that area but a deep clean will have to wait for another day as other jobs need attention along with a family wanting to head out for the afternoon.

Oh and whilst the vehicle was jacked up with the rear axel free I decided to quickly fit the shiny new WhiteLine Rear Anti-Roll Bar:

Adhered to the instructions which were pretty easy to follow. I’ve bolted it up on the medium setting and will trial that for a week or 2 the try the other 2 available settings.

About to put the wheels back on, clean up and go for a test drive.

I’ll report back this evening if there is the need to do so; otherwise I’ll next report on the ARB when I get round to trialling the softer and harder setting.

Kind regards,

Tom

These are the rear shocks that I’ve just removed:

Yes they have the 8Z0 part number stamped on so guessing the else are some 23 years old. The dust covers are also original too.

You’ve already seen the new shock earlier but here they are fitted:

Quite dirty in and around that area but a deep clean will have to wait for another day as other jobs need attention along with a family wanting to head out for the afternoon.

Oh and whilst the vehicle was jacked up with the rear axel free I decided to quickly fit the shiny new WhiteLine Rear Anti-Roll Bar:

Adhered to the instructions which were pretty easy to follow. I’ve bolted it up on the medium setting and will trial that for a week or 2 the try the other 2 available settings.

About to put the wheels back on, clean up and go for a test drive.

I’ll report back this evening if there is the need to do so; otherwise I’ll next report on the ARB when I get round to trialling the softer and harder setting.

Kind regards,

Tom

2work

Well Known Member

Hello again,

Thought I’d provide a quick update after a 10 mile test drive around the local roads of varying speeds and corners. All I can say is….. Utterly brilliant. The feeling of the stiffer rear is really nice along with the fresh shocks and springs. Such a difference than what I had become accustomed to.

What a significant upgrade the rear ARB is. As much as I like the precision it feels to provide, I will of course try the harder and softer setting in the coming weeks.

What a completely satisfying hours spannering whilst the rain clouds held off.

Think the next big job is to rub the rear axel, provide some rust treatment and treat it to a coat or paint. A task for the summer months when the treatment and paint products can correctly cure with a reasonably warm ambient temperature.

Kind regards,

Tom

Thought I’d provide a quick update after a 10 mile test drive around the local roads of varying speeds and corners. All I can say is….. Utterly brilliant. The feeling of the stiffer rear is really nice along with the fresh shocks and springs. Such a difference than what I had become accustomed to.

What a significant upgrade the rear ARB is. As much as I like the precision it feels to provide, I will of course try the harder and softer setting in the coming weeks.

What a completely satisfying hours spannering whilst the rain clouds held off.

Think the next big job is to rub the rear axel, provide some rust treatment and treat it to a coat or paint. A task for the summer months when the treatment and paint products can correctly cure with a reasonably warm ambient temperature.

Kind regards,

Tom

Last edited:

CrispyEdd

Member

Good work Tom, I've just wired drilled my axle and rust treated it.Hello again,

Thought I’d provide a quick update after a 10 mile test drive around the local roads of varying speeds and corners. All I can say is….. Utterly brilliant. The feeling of the stiffer rear is really nice along with the fresh shocks and springs. Such a difference than what I had become accustomed to.

What a significant upgrade the rear ARB is. As much as I like the precision it feels to provide, I will of course try the harder and softer setting in the coming weeks.

What a completely satisfying hours spannering whilst the rain clouds held off.

Think the next big job is to rub the rear axel, provide some rust treatment and treat it to a coat or paint. A task for the summer months when the treatment and paint products can correctly cure with a reasonably warm ambient temperature.

Kind regards,

Tom

2work

Well Known Member

Good work Edd,Good work Tom, I've just wired drilled my axle and rust treated it.looks great now

I’ll do this when I’m next under there car whilst adjusting the setting of the rear ARB. I would have done it earlier. It time was against me.

What products did you use Sir.

Kind regards,

Tom

CrispyEdd

Member

Neutrarust 661® Rust Converter &... https://www.amazon.co.uk/dp/B08ZDT4GXP?ref=ppx_pop_mob_ap_shareGood work Edd,

I’ll do this when I’m next under there car whilst adjusting the setting of the rear ARB. I would have done it earlier. It time was against me.

What products did you use Sir.

Kind regards,

Shoukd have taken s**t before but it was fairly bad and flaky!

2work

Well Known Member

Hello all,

After going out on yesterday’s 10 mile test drive with just me in the vehicle, the positive feeling that I had was such a welcomed change that I honestly didn’t know I required. The difference of the new rear shock absorbers along with the rear ARB and accompanying the recent new springs is simply night and day.

After the new rear springs the annoying tyre rub was cured, well so I first thought, but travelling 4-up I would get the the occasional rub when going over speed bumps if I was travelling in excess of 10mph.

Therefore the real test was conducted yesterday evening when we headed out as a family along the usual route where this occasional wheel arch/tyre rub would occur. All I have to report is that there is absolutely no more rubbing of any kind and this was me driving a little bit faster than I probably should have over the speed bumps.

Completely cured these issues and a much more precise feeling now. Such a nice spot of spannering yesterday. The rear ARB upgrade is well worth the money; £150-£170 depending of deals/discount codes is a no brainer for me…

I’ll be purchasing another one for the Project OEM A2 soon enough as that particular vehicle could do with a complete front and rear suspension refresh. B4s with KYB springs seem to have worked perfectly on this A2 so I’ll probably go for the same again.

Kind regards,

Tom

After going out on yesterday’s 10 mile test drive with just me in the vehicle, the positive feeling that I had was such a welcomed change that I honestly didn’t know I required. The difference of the new rear shock absorbers along with the rear ARB and accompanying the recent new springs is simply night and day.

After the new rear springs the annoying tyre rub was cured, well so I first thought, but travelling 4-up I would get the the occasional rub when going over speed bumps if I was travelling in excess of 10mph.

Therefore the real test was conducted yesterday evening when we headed out as a family along the usual route where this occasional wheel arch/tyre rub would occur. All I have to report is that there is absolutely no more rubbing of any kind and this was me driving a little bit faster than I probably should have over the speed bumps.

Completely cured these issues and a much more precise feeling now. Such a nice spot of spannering yesterday. The rear ARB upgrade is well worth the money; £150-£170 depending of deals/discount codes is a no brainer for me…

I’ll be purchasing another one for the Project OEM A2 soon enough as that particular vehicle could do with a complete front and rear suspension refresh. B4s with KYB springs seem to have worked perfectly on this A2 so I’ll probably go for the same again.

Kind regards,

Tom

D

Deleted member 20348

Guest

@CrispyEdd

Your driveway looks painful to work on. Road stone? Caution loose chipping dinted knees

Your driveway looks painful to work on. Road stone? Caution loose chipping dinted knees

CrispyEdd

Member

Indeed mate, it's barbaric! I use sheets and food delivery insulation pads! It's blinking hard to find a dropped screw or nut!!@CrispyEdd

Your driveway looks painful to work on. Road stone? Caution loose chipping dinted knees

2work

Well Known Member

Morning all,

Not much has happened with this lovely A2 this last week. I can certainly state that after diving a bit this last week though that the fresh rear suspension feels absolutely spot on, even 4-up. The Whiteline Rear ARB is also still providing a fantastic positive feeling too. I’ve adjusted fitting to the softer setting and will trial that for a week, then report back.

Had to pop out last night to do a spot of shopping and just had to take a shot of the car in the local Morrisons car park:

Still on awe of how this car looks with the full Votex kit and the A8 D2 wheels. I could take pictures if it hours and not get bored!

More to follow regards the softer ARB setting once I’ve done a few more miles.

Kind regards,

Tom

Not much has happened with this lovely A2 this last week. I can certainly state that after diving a bit this last week though that the fresh rear suspension feels absolutely spot on, even 4-up. The Whiteline Rear ARB is also still providing a fantastic positive feeling too. I’ve adjusted fitting to the softer setting and will trial that for a week, then report back.

Had to pop out last night to do a spot of shopping and just had to take a shot of the car in the local Morrisons car park:

Still on awe of how this car looks with the full Votex kit and the A8 D2 wheels. I could take pictures if it hours and not get bored!

More to follow regards the softer ARB setting once I’ve done a few more miles.

Kind regards,

Tom

CrispyEdd

Member

Love those wheel and kit, really strong look. Like the way you made the Mrs stand and wait while you took pictures.Morning all,

Not much has happened with this lovely A2 this last week. I can certainly state that after diving a bit this last week though that the fresh rear suspension feels absolutely spot on, even 4-up. The Whiteline Rear ARB is also still providing a fantastic positive feeling too. I’ve adjusted fitting to the softer setting and will trial that for a week, then report back.

Had to pop out last night to do a spot of shopping and just had to take a shot of the car in the local Morrisons car park:

View attachment 120409

Still on awe of how this car looks with the full Votex kit and the A8 D2 wheels. I could take pictures if it hours and not get bored!

More to follow regards the softer ARB setting once I’ve done a few more miles.

Kind regards,

Tom

2work

Well Known Member

Morning Edd,Love those wheel and kit, really strong look. Like the way you made the Mrs stand and wait while you took pictures.

It wasn’t the wife but was the eldest, who wasn’t happy at all to be in a supermarket car park waiting to get in whilst I had the phone in camera mode. Was worried any of his friends would see us, haha.

Yes it’s a strong look indeed. Which I absolutely love. Makes me want another Jaipur Red A2 to put the spare full Votex kit not on. I have my eye on an Arctic/Polar White A2 but if that falls through then I’ll be after searching for another Jaipur!

Kind regards,

Tom

2work

Well Known Member

Hello all,

Some of you will have seen on the Today I… thread that I was unfortunate to loose something on the way home Saturday evening after a slot of shopping and taking this picture:

The car wasn’t used on Sunday or Monday but noticed that something h was missing when walking out of the local post office yesterday morning:

I’m sure you can see what’s missing which is rather annoying as it’s an almost irreplaceable genuine item. Gutted as I thought it was held in place quite well. Silicone will be unused from now on instead of strips of 3M VHB tape!

Whilst out on my mid morning walk earlier today to the same Morrison’s I noticed something in the middle of the road, just short of the roundabout literally 1 mile from 2Work Towers:

I waited for a gap in the busy traffic to cross the road to the pedestrian crossing island to investigate further as it appeared to be what I was missing:

When a safe opportunity presented itself I stepped closer to see if it was what I was hoping it was:

I couldn’t believe my luck in this unfortunate situation. It looked in a rather sorry state and had probably been driven over countless time the previous 72 hours!

Once back on the pedestrian island I had a look at the line side to see if it was possible to repair:

Didn’t look too bad but waited until I bit home to wash it and take a closer look. Here it is back on the workbench, some people here calm it the kitchen island. It it’s certainly the workbench when home-alone haha:

Just hit the quota of 8 pictures in this particular post so will add further pictures in the next.

As you can see above, it’s in a right sorry state but quite sure it’ll be quite useable after some Dremel action, plastic welding, sanding, filling, more sanding, paint and finally clear coat.

The obvious split and filled with 2 part epoxy to ensure good adhesion and also clamped whilst the adhesive cured. Once the epoxy has hardened, the real work started on an attempt to rescue the genuine item from file 13.

First up was to sand the painted surface to check for any other damage/fractures.,,

About time for another picture so will continued in the next list.

Kind regards,

Tom

Some of you will have seen on the Today I… thread that I was unfortunate to loose something on the way home Saturday evening after a slot of shopping and taking this picture:

The car wasn’t used on Sunday or Monday but noticed that something h was missing when walking out of the local post office yesterday morning:

I’m sure you can see what’s missing which is rather annoying as it’s an almost irreplaceable genuine item. Gutted as I thought it was held in place quite well. Silicone will be unused from now on instead of strips of 3M VHB tape!

Whilst out on my mid morning walk earlier today to the same Morrison’s I noticed something in the middle of the road, just short of the roundabout literally 1 mile from 2Work Towers:

I waited for a gap in the busy traffic to cross the road to the pedestrian crossing island to investigate further as it appeared to be what I was missing:

When a safe opportunity presented itself I stepped closer to see if it was what I was hoping it was:

I couldn’t believe my luck in this unfortunate situation. It looked in a rather sorry state and had probably been driven over countless time the previous 72 hours!

Once back on the pedestrian island I had a look at the line side to see if it was possible to repair:

Didn’t look too bad but waited until I bit home to wash it and take a closer look. Here it is back on the workbench, some people here calm it the kitchen island. It it’s certainly the workbench when home-alone haha:

Just hit the quota of 8 pictures in this particular post so will add further pictures in the next.

As you can see above, it’s in a right sorry state but quite sure it’ll be quite useable after some Dremel action, plastic welding, sanding, filling, more sanding, paint and finally clear coat.

The obvious split and filled with 2 part epoxy to ensure good adhesion and also clamped whilst the adhesive cured. Once the epoxy has hardened, the real work started on an attempt to rescue the genuine item from file 13.

First up was to sand the painted surface to check for any other damage/fractures.,,

About time for another picture so will continued in the next list.

Kind regards,

Tom

2work

Well Known Member

Me again,

Continuing from the previous post.

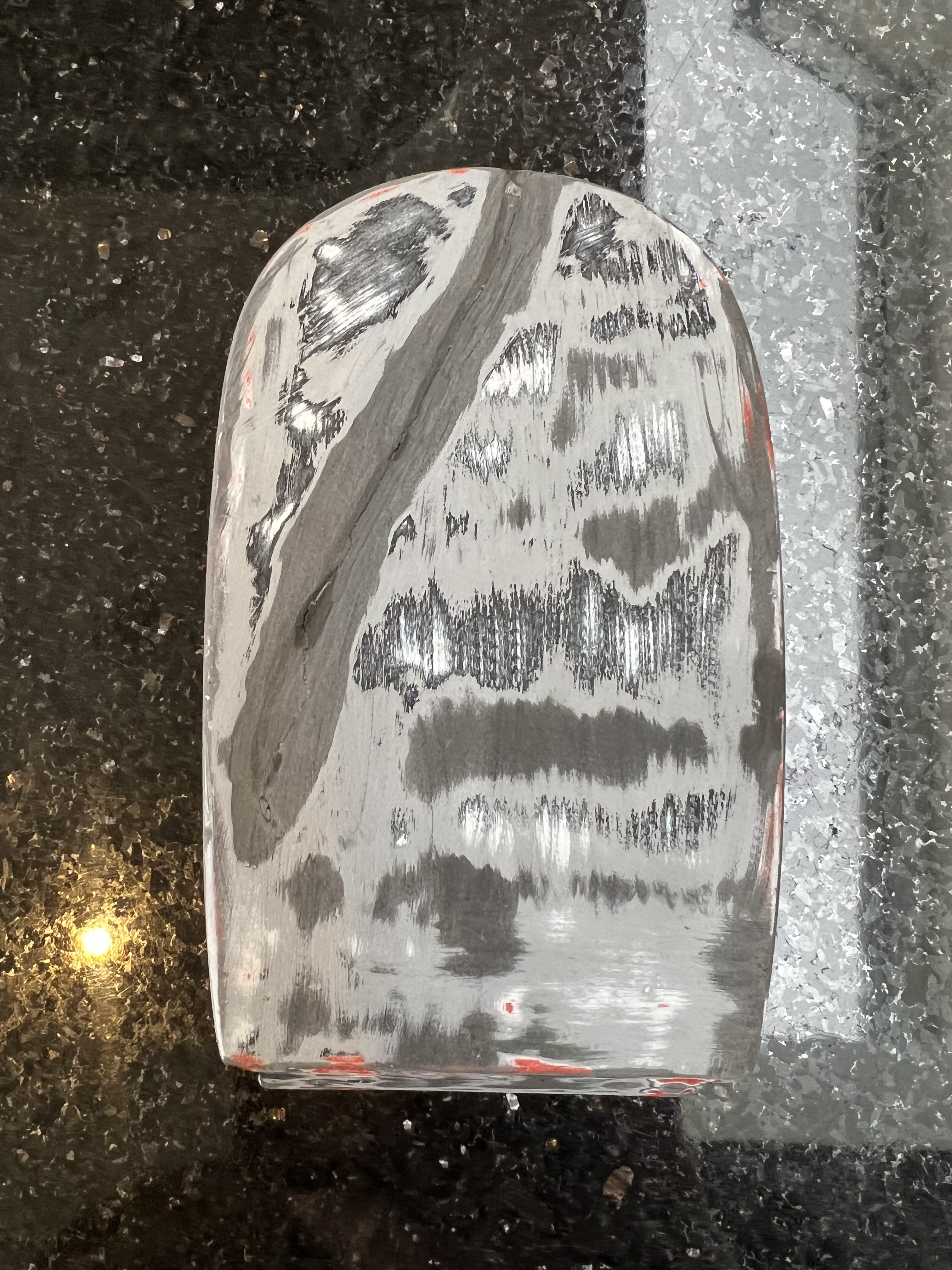

Here’s the cover with the paint removed with the Dremel with a sanding wheel attached to quickly get the the plastic for inspection. I also used a stone wheel attachment to grind a channel along the obvious split to conduct a slot of plastic welding:

I actually don’t possess a plastic welding kit so have since got one on order for situations like this in the future. Being the impatient person that I can at times, I decided to continue with the plastic welding with the soldering iron with a tip that I don’t use for the retrofits I conduct. I used 2 different plastics for the this repair:

Thin line fibre composite plastic for strength

Wider, more flush line of flexible plastic

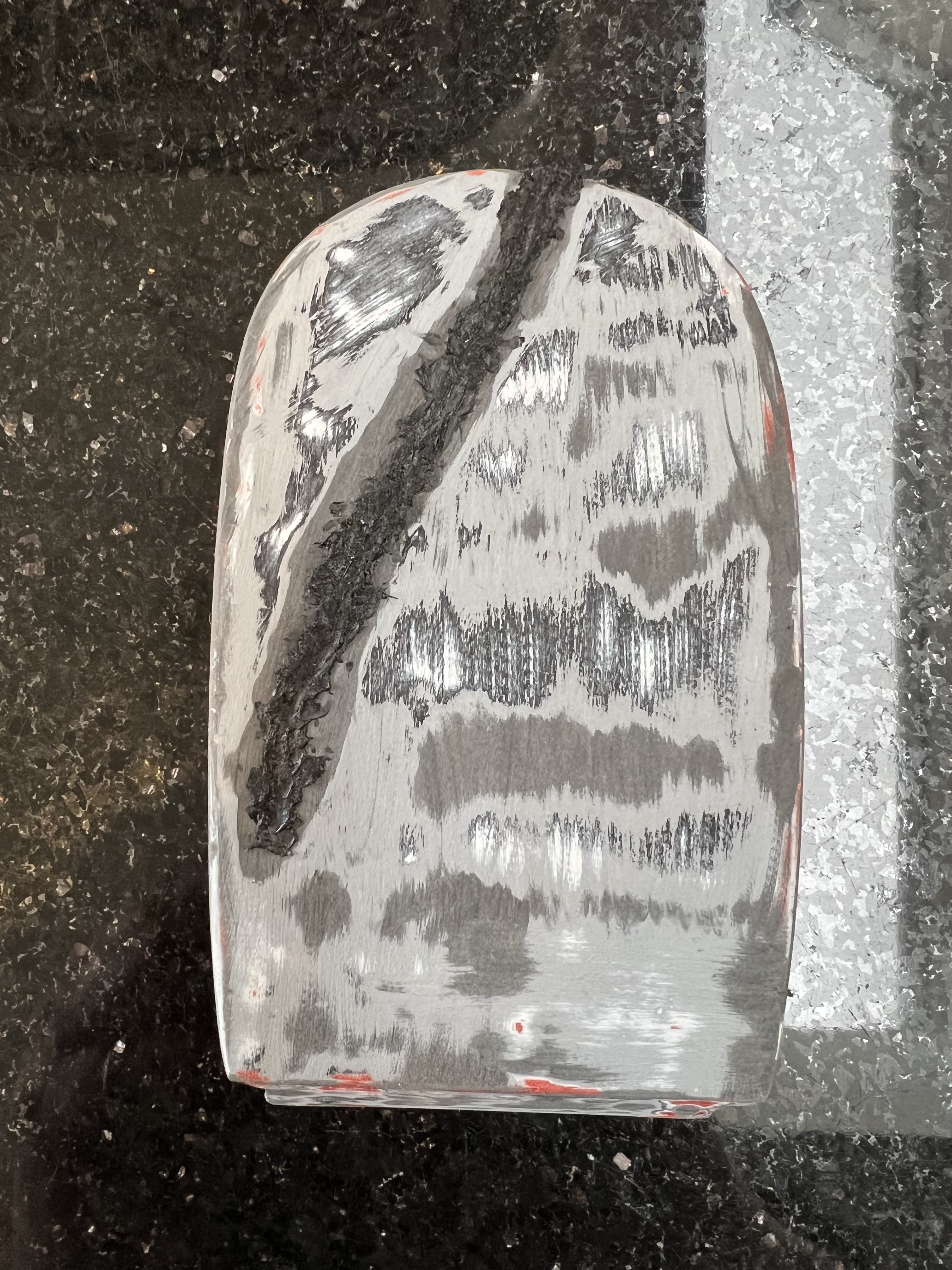

Yes it looks untidy but was persevering with what I had available this afternoon. Here’s the cover after a couple of minutes of 120 grit (wet):

It was starting to look like this repair might just work out. Next up was to find the filler that I purchased over the festive period to tidy up my factory tailgate spoiler ahead of it being sealed over into Neil’s @nee777.a2 A2. I couldn’t find the applicator though so used a a credit card and went thick as the credit card wasn’t that good at achieving an all over smooth finish:

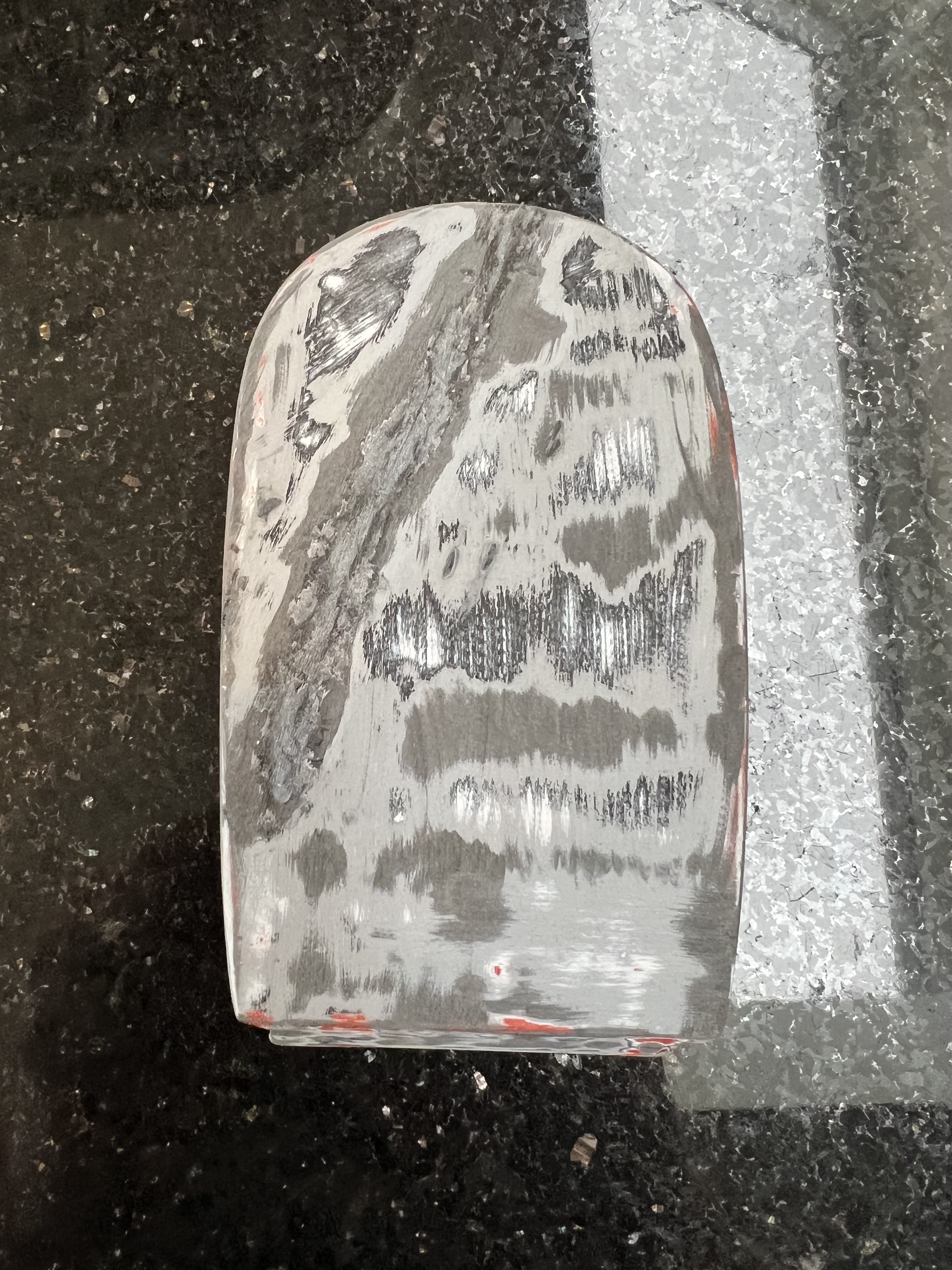

After a few minutes transitioning from 240 grit (wet) to 400 grit (wet) the cover started to look a lot better and the dread of having to locate another genuine Votex jacking point cover was dissolving:

Couple of pin holes in the filler which was due to me Sandi g a few minutes too early and pulled the finish. Should have waited another 10 minutes and all would have been a little better. I had self induced pressure to get the task completed in between meetings and commitments and really should have waited until the weekend when I had more time. Hindsight!

Next up was to apply a few layers of primer and sand it back with the 800 grit (wet), as shown below:

Almost out of room again on the picture count so will wrap this up by skipping the pictures of the top coat stage and just show the end result post clear coat. The top coat I used was the very same tin tha t was used for the Rear PDC sensors. Probably got a good 8 layers applied, starting them with heat in between each layer. I didn’t sand after the top coat and went straight to clear coat after heat - wait 10 minutes - heat. I used up 2/3s of a tin of clear coat which is what was left after the Rear PDC Sensor recolouring.

apologies for dragging this out as I’m sure out want to see how it looks right now:

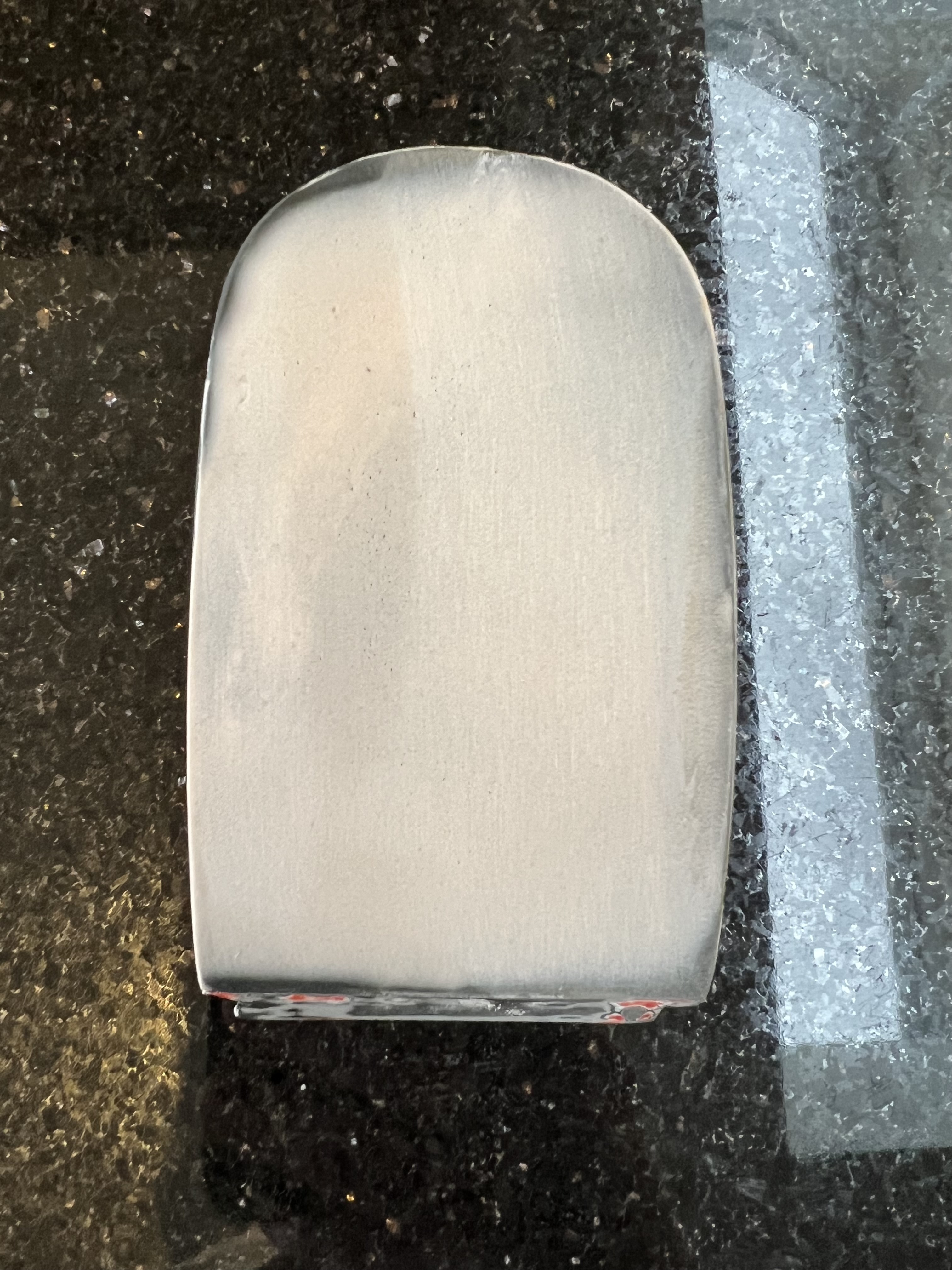

Here is the revitalised Votex jacking point cover:

Such a difference from what I picked up from the road earlier this morning. You’ll possibly see a few imperfections which will no doubt will be removed when it’s been wet sanded with 3000 grit once the products have fully cured. Any remaining blemishes I will just live with as it’s certainly better than it looked just before lunchtime.

I’m of course over the moon with finding this item and how it’s come out so far but the morale of the story is; use silicone (or even a tether) to adhere the jacking point covers in once so they never fall out.

Kind regards,

Tom

Continuing from the previous post.

Here’s the cover with the paint removed with the Dremel with a sanding wheel attached to quickly get the the plastic for inspection. I also used a stone wheel attachment to grind a channel along the obvious split to conduct a slot of plastic welding:

I actually don’t possess a plastic welding kit so have since got one on order for situations like this in the future. Being the impatient person that I can at times, I decided to continue with the plastic welding with the soldering iron with a tip that I don’t use for the retrofits I conduct. I used 2 different plastics for the this repair:

Thin line fibre composite plastic for strength

Wider, more flush line of flexible plastic

Yes it looks untidy but was persevering with what I had available this afternoon. Here’s the cover after a couple of minutes of 120 grit (wet):

It was starting to look like this repair might just work out. Next up was to find the filler that I purchased over the festive period to tidy up my factory tailgate spoiler ahead of it being sealed over into Neil’s @nee777.a2 A2. I couldn’t find the applicator though so used a a credit card and went thick as the credit card wasn’t that good at achieving an all over smooth finish:

After a few minutes transitioning from 240 grit (wet) to 400 grit (wet) the cover started to look a lot better and the dread of having to locate another genuine Votex jacking point cover was dissolving:

Couple of pin holes in the filler which was due to me Sandi g a few minutes too early and pulled the finish. Should have waited another 10 minutes and all would have been a little better. I had self induced pressure to get the task completed in between meetings and commitments and really should have waited until the weekend when I had more time. Hindsight!

Next up was to apply a few layers of primer and sand it back with the 800 grit (wet), as shown below:

Almost out of room again on the picture count so will wrap this up by skipping the pictures of the top coat stage and just show the end result post clear coat. The top coat I used was the very same tin tha t was used for the Rear PDC sensors. Probably got a good 8 layers applied, starting them with heat in between each layer. I didn’t sand after the top coat and went straight to clear coat after heat - wait 10 minutes - heat. I used up 2/3s of a tin of clear coat which is what was left after the Rear PDC Sensor recolouring.

apologies for dragging this out as I’m sure out want to see how it looks right now:

Here is the revitalised Votex jacking point cover:

Such a difference from what I picked up from the road earlier this morning. You’ll possibly see a few imperfections which will no doubt will be removed when it’s been wet sanded with 3000 grit once the products have fully cured. Any remaining blemishes I will just live with as it’s certainly better than it looked just before lunchtime.

I’m of course over the moon with finding this item and how it’s come out so far but the morale of the story is; use silicone (or even a tether) to adhere the jacking point covers in once so they never fall out.

Kind regards,

Tom